一、基本情況

江蘇天淮鋼(gang)管(guan)(guan)(guan)有(you)(you)限(xian)公司(si)φ508mm(20in)PQF連(lian)(lian)軋(ya)管(guan)(guan)(guan)機組(zu)(zu),是目前全(quan)球最大(da)(da)口徑的三輥(gun)式連(lian)(lian)軋(ya)管(guan)(guan)(guan)機組(zu)(zu),2012年(nian)5月(yue)28日熱負荷試車成功(gong)。該(gai)機組(zu)(zu)由中冶京誠(cheng)工(gong)程技術有(you)(you)限(xian)公司(si)做(zuo)工(gong)廠設計(ji)(ji),主軋(ya)線設備由德國梅爾公司(si)、意(yi)大(da)(da)利因西設計(ji)(ji)制造,設計(ji)(ji)能力(li)為(wei)年(nian)產無縫鋼(gang)管(guan)(guan)(guan)50萬(wan)噸。自投(tou)產半年(nian)時間里(li),生產Φ377~508mm 規格鋼(gang)管(guan)(guan)(guan)共3.8萬(wan)噸,產品質量優良。

二、產品規格(ge)和主(zhu)要品種

1. 產(chan)品規格

外徑:φ245~508mm;

壁厚:6.1~60mm;

長度(du):6~15m。

2. 主要品種(zhong)

管線管、鍋爐用管、氣瓶管、機械管、液壓(ya)支柱(zhu)管,流(liu)體輸送管、結構管等。

3. 工(gong)藝(yi)流程(cheng)

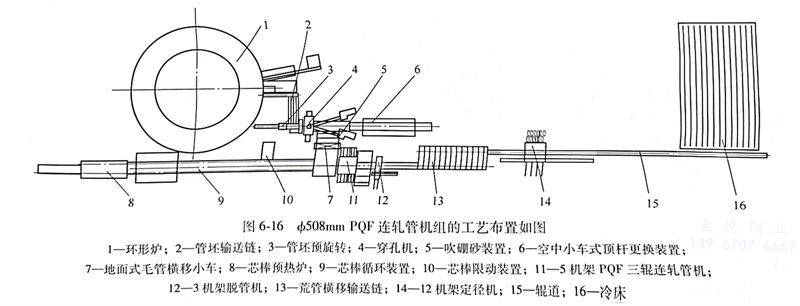

φ508mm PQF連(lian)軋管機組的工藝(yi)布(bu)置如圖6-16所示(shi)。

工藝(yi)流程(cheng)為:合格管坯→鋸(ju)切→冷定心→環形爐加熱→高壓水除磷→穿(chuan)孔(kong)→吹硼砂→穿(chuan)芯棒→高壓水除鱗→F連軋→脫管→高壓水除鱗→定徑→冷卻→定尺鋸(ju)切→矯直→吹吸灰→探傷→人工內外表(biao)面檢(jian)查→噴標→收集入庫。

三個變形主機由(you)帶管坯預旋轉(zhuan)的(de)錐形輥導(dao)板式穿孔機、5機架PQF限動芯棒(bang)連(lian)軋管機、12架單獨傳動的(de)定徑(jing)機組(zu)成,三大主機本(ben)體設(she)(she)(she)備都由(you)德國MEER公(gong)(gong)司設(she)(she)(she)計制(zhi)造,主機設(she)(she)(she)備前后臺連(lian)線設(she)(she)(she)備由(you)中冶(ye)京(jing)誠工程技術有限公(gong)(gong)司設(she)(she)(she)計,天津賽瑞機器制(zhi)造有限公(gong)(gong)司制(zhi)造。φ508PQF機組(zu)采用更為完善的(de)先(xian)(xian)進工藝(yi)控(kong)制(zhi)系統(tong)(tong)(tong)-CARTA系統(tong)(tong)(tong)、嚴格的(de)質(zhi)量控(kong)制(zhi)系統(tong)(tong)(tong)-QAS系統(tong)(tong)(tong)、物料跟(gen)蹤系統(tong)(tong)(tong)(MTS)以及(ji)在線檢測系統(tong)(tong)(tong)等(deng)工藝(yi)控(kong)制(zhi)技術,從而確保了熱(re)軋大口(kou)徑(jing)無縫鋼管生產的(de)工藝(yi)先(xian)(xian)進性及(ji)穩(wen)定性。

四、主要工藝設備及性能特點

1. 環形(xing)加熱爐

環形(xing)爐(lu)(lu)由LOI天(tian)津公司設(she)計及制(zhi)(zhi)作(zuo),為(wei)(wei)降低成本,采用(yong)高爐(lu)(lu)煤(mei)氣(qi)和天(tian)然(ran)氣(qi)混合氣(qi)作(zuo)為(wei)(wei)燃(ran)料(liao)。從裝(zhuang)料(liao)到出料(liao)共(gong)分(fen)7個(ge)加(jia)熱控制(zhi)(zhi)段,其(qi)中(zhong)第1~2段為(wei)(wei)預熱段,第3~5段為(wei)(wei)加(jia)熱段,第6~7段為(wei)(wei)均(jun)熱段;其(qi)中(zhong)預熱2段和加(jia)熱段采用(yong)高爐(lu)(lu)煤(mei)氣(qi)蓄熱燒(shao)嘴(zui),均(jun)熱段用(yong)頂置(zhi)的天(tian)然(ran)氣(qi)平(ping)焰燒(shao)嘴(zui)均(jun)熱,環形(xing)爐(lu)(lu)采用(yong)全(quan)自(zi)動、先進、可靠(kao)的熱工(gong)控制(zhi)(zhi)系統測量和控制(zhi)(zhi)爐(lu)(lu)子(zi)的熱工(gong)過(guo)程(cheng),可根據不同工(gong)況準(zhun)確匹配(pei)爐(lu)(lu)子(zi)供熱量,保證管坯按最佳的工(gong)藝曲線加(jia)熱和保溫。

環形(xing)加熱爐主要參數包(bao)括(kuo):

中徑(jing):51m;

爐底(di)寬(kuan)度:5.4m;

最(zui)大加熱長度(du):5.0m;

最大坯重:7620kg;

最大加熱能力(li):260t/h;

最大裝出料節(jie)奏:90p/h。

2. 錐形輥(gun)穿孔機

該機組采用導板式錐形輥立式穿孔機,在18in PQF機組基礎上,穿孔輥直徑從1500mm增大到1700mm,電機功率從6500kW2臺增加到8200kW×2臺,提高穿孔機的變形能力,減少連軋機的變形負荷;采用導板式主要目的是穿孔機孔型封閉性好、毛管壁厚精度高,減少了導盤傳動系統,減小了牌坊的尺寸,降低了設備投資。

由于本機組(zu)采(cai)用(yong)的管(guan)坯(pi)直徑(Φ310mm、ф380mm、Φ450mm、φ500mm)比18in機組(zu)管(guan)坯(pi)直徑大(da),管(guan)坯(pi)重(zhong)量也大(da),為(wei)方便(bian)管(guan)坯(pi)咬(yao)入(ru),防止前卡(ka)事故(gu),在前臺設置了(le)管(guan)坯(pi)預(yu)旋(xuan)轉(zhuan)裝置,見圖6-17,大(da)管(guan)坯(pi)在推鋼機推入(ru)軋輥前在預(yu)旋(xuan)轉(zhuan)的驅動下旋(xuan)轉(zhuan)起來,這樣很(hen)大(da)程度改善(shan)了(le)咬(yao)入(ru)條件,減少了(le)事故(gu),提高了(le)軋輥壽命。

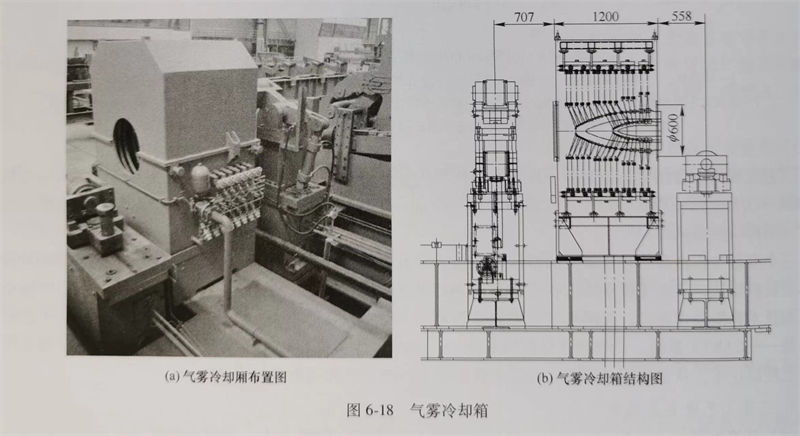

該穿孔機后(hou)(hou)臺一(yi)(yi)段有(you)6組(zu)三輥定(ding)心(xin)裝置,后(hou)(hou)臺二段的(de)頂(ding)(ding)(ding)桿(gan)(gan)采用在(zai)線小車(che)上下料(liao)、頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)采用內(nei)部(bu)(bu)(bu)(bu)循(xun)環(huan)(huan)(huan)水冷(leng)(leng)加外部(bu)(bu)(bu)(bu)氣(qi)(qi)霧(wu)冷(leng)(leng)卻(que)(que)方(fang)式(shi),當(dang)頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)穿廢時隨頂(ding)(ding)(ding)桿(gan)(gan)一(yi)(yi)起更(geng)換,見圖6-18所示(shi)。頂(ding)(ding)(ding)桿(gan)(gan)上料(liao)后(hou)(hou)冷(leng)(leng)卻(que)(que)水可直接循(xun)環(huan)(huan)(huan)到(dao)頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)工(gong)作段的(de)內(nei)腔,在(zai)軋(ya)制(zhi)(zhi)及間(jian)(jian)歇(xie)(xie)不(bu)管頂(ding)(ding)(ding)桿(gan)(gan)在(zai)什么位(wei)置,都(dou)能通(tong)過內(nei)部(bu)(bu)(bu)(bu)循(xun)環(huan)(huan)(huan)水對(dui)頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)快速冷(leng)(leng)卻(que)(que);在(zai)軋(ya)制(zhi)(zhi)間(jian)(jian)歇(xie)(xie)時頂(ding)(ding)(ding)桿(gan)(gan)回(hui)退(tui)到(dao)基位(wei)后(hou)(hou),進入有(you)外部(bu)(bu)(bu)(bu)氣(qi)(qi)霧(wu)冷(leng)(leng)卻(que)(que)箱對(dui)頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)進行(xing)外部(bu)(bu)(bu)(bu)冷(leng)(leng)卻(que)(que),氣(qi)(qi)霧(wu)冷(leng)(leng)卻(que)(que)箱中的(de)15道水環(huan)(huan)(huan)分4組(zu)控制(zhi)(zhi),從圓周方(fang)向分別(bie)對(dui)頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)不(bu)同部(bu)(bu)(bu)(bu)位(wei)分別(bie)控制(zhi)(zhi)時間(jian)(jian)控制(zhi)(zhi)水量來冷(leng)(leng)卻(que)(que),從而保證(zheng)了頂(ding)(ding)(ding)頭(tou)(tou)(tou)(tou)工(gong)作段良好的(de)冷(leng)(leng)卻(que)(que)效(xiao)果。

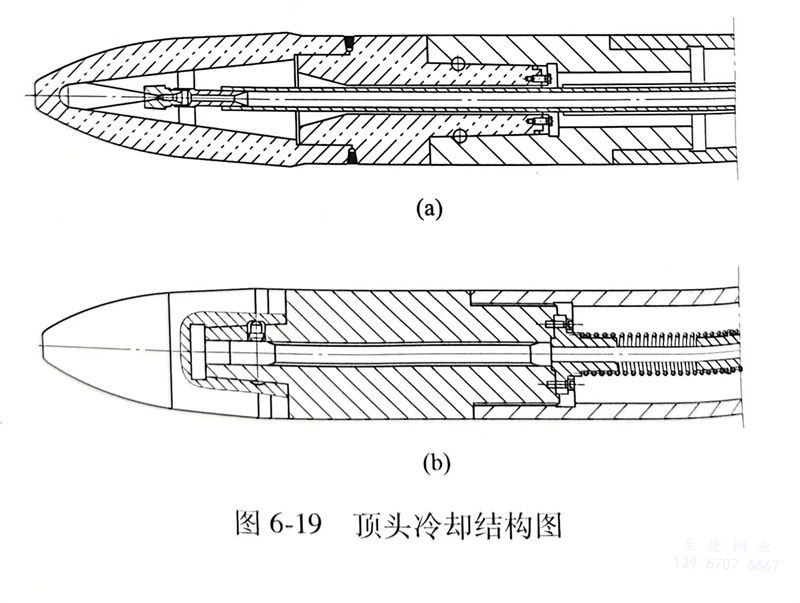

在以前18英寸PQF機組基礎(chu)上頂(ding)頭(tou)(tou)冷(leng)卻形式做了很大改(gai)進(jin),見圖6-19(其中,圖6-19為本機組頂(ding)頭(tou)(tou)結構(gou),圖6-19(b)為原18in頂(ding)頭(tou)(tou)結構(gou)),頂(ding)頭(tou)(tou)由原來的(de)實心體改(gai)為空腔體,以至(zhi)于(yu)內部冷(leng)卻水能一直貫通整個(ge)頂(ding)頭(tou)(tou)的(de)內腔,使頂(ding)頭(tou)(tou)的(de)尖端及(ji)工作(zuo)段(duan)能得(de)到徹底冷(leng)卻,從而延長了頂(ding)頭(tou)(tou)壽命。

本機組的毛管橫移采用可伸縮(suo)的大擺臂移送(song)(song)到(dao)硼砂工位,吹(chui)完硼砂后(hou)由帶擺動撥叉地面小車將(jiang)毛管移送(song)(song)到(dao)PQF連軋機前臺。

穿孔機(ji)主要參數(shu)包(bao)括:

最大(da)/最小軋(ya)輥直徑:1700mm/1550mm;

最大出口速度:0.8m/s;

最大軋制力矩:3165kN·m;

主電(dian)機功(gong)率:8200kW×2臺(tai);

主電機最大轉速:354r/min;

氣霧(wu)冷卻系統:水壓0.5~0.7MPa;氣壓0.4~0.5MIPa。

3. PQF連軋(ya)管機

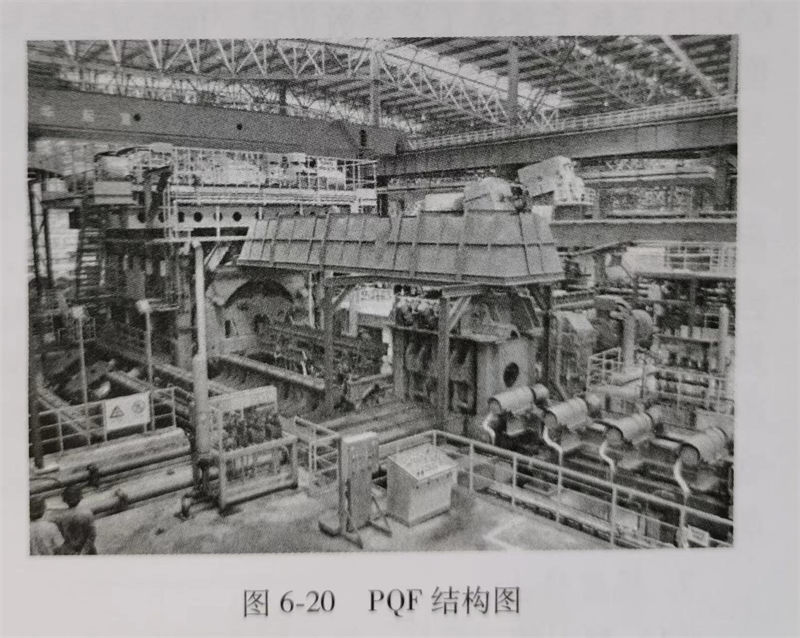

本機(ji)(ji)(ji)組PQF連(lian)軋(ya)管機(ji)(ji)(ji)為5機(ji)(ji)(ji)架(jia)的(de)(de)(de)軸向換(huan)輥(gun)連(lian)軋(ya)管機(ji)(ji)(ji)見圖6-20,優(you)點(dian)是隧道式筒形牌(pai)坊剛度(du)及強度(du)好(hao),傳動布置緊湊,軋(ya)制(zhi)(zhi)穩定性好(hao)。每架(jia)軋(ya)機(ji)(ji)(ji)的(de)(de)(de)三個互成120°的(de)(de)(de)軋(ya)輥(gun)安裝(zhuang)在獨立的(de)(de)(de)軋(ya)制(zhi)(zhi)單(dan)元(yuan)一軋(ya)輥(gun)小機(ji)(ji)(ji)架(jia)內,安裝(zhuang)在隧道上的(de)(de)(de)伺(si)服(fu)液壓(ya)小倉,可以對軋(ya)輥(gun)輥(gun)縫(feng)進行同步調整也(ye)可以單(dan)獨調整,即采(cai)用了輥(gun)縫(feng)自動控制(zhi)(zhi)系統(HCCS),從而(er)保證了軋(ya)制(zhi)(zhi)質(zhi)量,另外,該連(lian)軋(ya)管機(ji)(ji)(ji)在生產(chan)過程中采(cai)用了工藝過程控制(zhi)(zhi)系統(PSS),實(shi)現了溫(wen)度(du)補償、咬入沖(chong)擊控制(zhi)(zhi)、錐形芯棒伺(si)服(fu)和(he)頭尾削尖等功(gong)能。

由于該機(ji)組軋(ya)制節奏較慢(man)(最(zui)快40s/支),只有(you)在線(xian)穿芯棒(bang)方式,不(bu)設(she)預(yu)穿線(xian),減(jian)少(shao)(shao)了芯棒(bang)在線(xian)數量,減(jian)少(shao)(shao)了芯棒(bang)與毛(mao)管接(jie)觸時間(jian),減(jian)少(shao)(shao)了毛(mao)管的溫降,提高了芯棒(bang)壽(shou)命,節省(sheng)了設(she)備投(tou)資(zi)。

連軋機(ji)主(zhu)要參數包括:

荒管外徑:ф294mm,φ383mm,φ454mm,φ530mm;

軋(ya)輥直徑:φ1060~1130mm;

最大入口速度:1.5m/s;

最(zui)大出口(kou)速(su)度:4.0m/s;

最(zui)大軋制力:620kN;

最大(da)軋(ya)制力矩:250kN·m;

電機(ji)功率:1~4號機(ji)架各3×1000kW,5機(ji)架為3×500kW;

限(xian)動力:2900kN;

限動電機(ji)功率:500kW×6臺;

限動最(zui)大前進速度:2.5m/s;

限動最(zui)大(da)返(fan)回速度:4.5m/s;

軋制(zhi)中限動速度:1.5m/s。

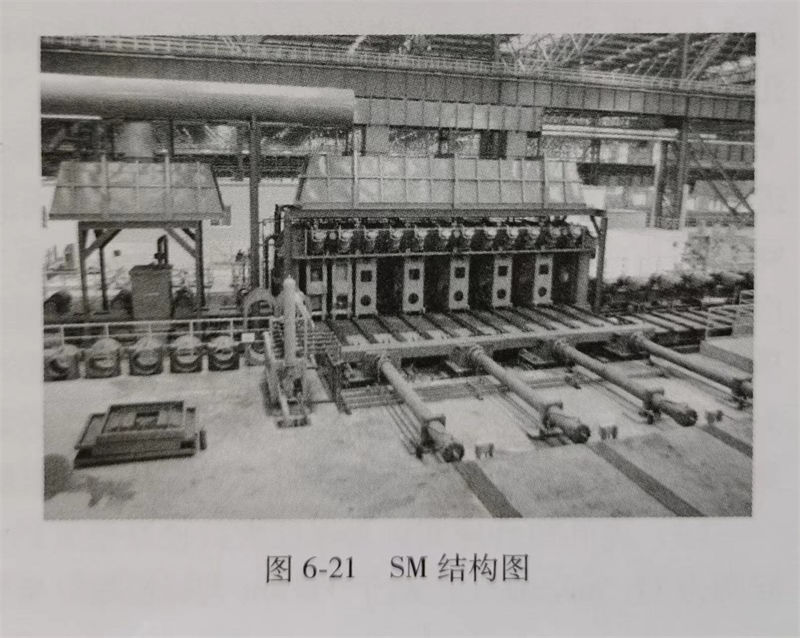

4. 定徑機

采(cai)(cai)用12架三輥(gun)(gun)式定(ding)徑機(ji),見(jian)圖6-21,每架都有一臺電機(ji)驅(qu)動,機(ji)架采(cai)(cai)用傘齒輪(lun)內傳動結構,在(zai)機(ji)架外有一根傳動軸通過聯軸器與12架組(zu)合式的減速器相連接(jie),奇偶架的電機(ji)前(qian)后排(pai)上下(xia)兩(liang)層排(pai)列(lie),整個定(ding)徑機(ji)布置(zhi)緊湊。該機(ji)組(zu)在(zai)定(ding)徑機(ji)前(qian)設置(zhi)了高(gao)壓(ya)水除鱗裝置(zhi),提高(gao)鋼管的外表面質量(liang),延長軋輥(gun)(gun)壽命。

定徑機(ji)主要參數包括:

軋輥名(ming)義直徑:φ1000mm;

機架間距:880mm;

入(ru)口(kou)鋼管速度:0.8~1.5m/s;

出口鋼管速度:0.85~2.0m/s;

電機(ji)功率(lv):350kW×12臺;

電機轉速:200~600/1200r/min。

五、機(ji)組工藝(yi)控制系統和質量保證系統

PQF三(san)輥(gun)連軋(ya)管機(ji)組(zu)(zu)數(shu)量(liang)的(de)(de)(de)(de)不斷增多,使(shi)得(de)PQF連軋(ya)管機(ji)的(de)(de)(de)(de)工(gong)(gong)藝控(kong)制(zhi)(zhi)系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)和(he)質(zhi)量(liang)保證系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)不斷提(ti)高完善,從而保證了更(geng)好的(de)(de)(de)(de)產(chan)(chan)品質(zhi)量(liang),更(geng)高的(de)(de)(de)(de)成(cheng)材率(lv)(lv)和(he)設(she)(she)備利用率(lv)(lv)以(yi)及較(jiao)低的(de)(de)(de)(de)工(gong)(gong)具(ju)消(xiao)耗。整個(ge)機(ji)組(zu)(zu)的(de)(de)(de)(de)過程管理(li)系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)包(bao)括(kuo)通常所說的(de)(de)(de)(de)MTS系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)、HCCS系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)、PSS系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)等在內的(de)(de)(de)(de)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)以(yi)及QAS系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)兩大部分組(zu)(zu)成(cheng)。整個(ge)熱軋(ya)線(xian)的(de)(de)(de)(de)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)是用來生(sheng)(sheng)產(chan)(chan)計劃(hua)及生(sheng)(sheng)產(chan)(chan)管理(li)的(de)(de)(de)(de)工(gong)(gong)藝控(kong)制(zhi)(zhi)系(xi)(xi)(xi)(xi)統(tong)(tong)(tong),由穿孔(kong)機(ji)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)、PQF軋(ya)管機(ji)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)及定(ding)徑機(ji)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)三(san)部分組(zu)(zu)成(cheng),其中PQF軋(ya)管CARTA是核心(xin)部分,穿孔(kong)機(ji)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)主(zhu)要是工(gong)(gong)藝參(can)(can)數(shu)設(she)(she)定(ding)、頂頭導(dao)板軋(ya)輥(gun)等軋(ya)制(zhi)(zhi)工(gong)(gong)具(ju)設(she)(she)計等內容;張減機(ji)CARTA系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)主(zhu)要是孔(kong)型設(she)(she)計、工(gong)(gong)藝參(can)(can)數(shu)設(she)(she)定(ding)等內容。QAS系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)是用于熱軋(ya)線(xian)質(zhi)量(liang)控(kong)制(zhi)(zhi)的(de)(de)(de)(de)檢測系(xi)(xi)(xi)(xi)統(tong)(tong)(tong)。

六、在線檢測質量保(bao)證系統(tong)QAS

QAS是一個在線獨立工(gong)作(zuo)站,通(tong)過對物料的(de)跟蹤檢(jian)測(ce)(ce)(ce),對數據(ju)進行收集分(fen)析和(he)(he)存儲(chu),并將分(fen)析的(de)結(jie)果及時反饋(kui)給CARTA系統以(yi)(yi)(yi)實(shi)施對物料的(de)控(kong)(kong)制(zhi)(zhi),保證鋼(gang)(gang)管(guan)(guan)質(zhi)量。QAS檢(jian)測(ce)(ce)(ce)的(de)具(ju)體(ti)內容(rong)包括:管(guan)(guan)坯稱重以(yi)(yi)(yi)控(kong)(kong)制(zhi)(zhi)坯料超重,實(shi)現坯料跟蹤;環形爐(lu)出口(kou)測(ce)(ce)(ce)溫以(yi)(yi)(yi)優化(hua)管(guan)(guan)坯加熱,滿足穿孔(kong)及連(lian)(lian)軋(ya)(ya)工(gong)藝(yi)要求(qiu),確保鋼(gang)(gang)管(guan)(guan)質(zhi)量;穿孔(kong)后測(ce)(ce)(ce)長以(yi)(yi)(yi)控(kong)(kong)制(zhi)(zhi)毛管(guan)(guan)幾何尺(chi)寸,確保連(lian)(lian)軋(ya)(ya)的(de)咬(yao)入及軋(ya)(ya)制(zhi)(zhi)的(de)穩(wen)定(ding)(ding);芯(xin)棒潤滑(hua)前測(ce)(ce)(ce)溫以(yi)(yi)(yi)滿足芯(xin)棒噴涂潤滑(hua)劑的(de)工(gong)藝(yi)要求(qiu),確保鋼(gang)(gang)管(guan)(guan)內表面質(zhi)量和(he)(he)芯(xin)棒使用壽命;連(lian)(lian)軋(ya)(ya)人口(kou)測(ce)(ce)(ce)溫以(yi)(yi)(yi)控(kong)(kong)制(zhi)(zhi)毛管(guan)(guan)溫度(du)確保軋(ya)(ya)機(ji)正常咬(yao)入及軋(ya)(ya)制(zhi)(zhi)的(de)穩(wen)定(ding)(ding)性(xing);連(lian)(lian)軋(ya)(ya)后測(ce)(ce)(ce)厚(hou)測(ce)(ce)(ce)長測(ce)(ce)(ce)溫以(yi)(yi)(yi)控(kong)(kong)制(zhi)(zhi)連(lian)(lian)軋(ya)(ya)出口(kou)荒(huang)管(guan)(guan)幾何尺(chi)寸,確保荒(huang)管(guan)(guan)壁厚(hou)精度(du);定(ding)(ding)徑前測(ce)(ce)(ce)溫以(yi)(yi)(yi)控(kong)(kong)制(zhi)(zhi)荒(huang)管(guan)(guan)溫度(du),確保定(ding)(ding)徑軋(ya)(ya)制(zhi)(zhi)穩(wen)定(ding)(ding)性(xing)。

七、機組特點

1. 增大(da)管坯直(zhi)徑,降低(di)穿孔的(de)(de)擴徑率,提高(gao)毛管的(de)(de)幾何(he)尺寸精度(du)

與相(xiang)近(jin)機組相(xiang)比(如表6-11所示(shi)),該機組增大(da)(da)管(guan)坯(pi)直(zhi)徑的(de)(de)意義在于:對(dui)于環形(xing)爐,大(da)(da)口徑厚壁管(guan)生產時降低(di)了(le)(le)(le)(le)坯(pi)料的(de)(de)長度,設(she)計中減少了(le)(le)(le)(le)環形(xing)爐的(de)(de)中徑,在環形(xing)爐建(jian)設(she)中減少了(le)(le)(le)(le)近(jin)5%投資(zi);對(dui)于穿(chuan)(chuan)孔機而言(yan),管(guan)坯(pi)外(wai)徑增大(da)(da)了(le)(le)(le)(le),但毛(mao)(mao)(mao)管(guan)的(de)(de)幾(ji)何尺寸和同類機組一樣(yang)(yang),這樣(yang)(yang)毛(mao)(mao)(mao)管(guan)的(de)(de)擴(kuo)徑率降低(di)了(le)(le)(le)(le)近(jin)10%,在穿(chuan)(chuan)孔斜(xie)軋過(guo)程中,大(da)(da)大(da)(da)降低(di)了(le)(le)(le)(le)軋件的(de)(de)橫向變形(xing),能很好抑制(zhi)穿(chuan)(chuan)孔的(de)(de)附加變形(xing)程度,提高毛(mao)(mao)(mao)管(guan)的(de)(de)幾(ji)何尺寸精(jing)度。

2. 穿孔機采用新(xin)型的頂(ding)桿(gan)頂(ding)頭連接(jie)形式(shi)和更換方(fang)式(shi)

與φ460機(ji)(ji)(ji)(ji)組(zu)(zu)相比,天淮(huai)508機(ji)(ji)(ji)(ji)組(zu)(zu)穿孔(kong)后臺(tai)二段形式徹底改進(jin),針對大機(ji)(ji)(ji)(ji)組(zu)(zu)節(jie)奏較慢(最快40s以上)的(de)特點,為提(ti)高設(she)備(bei)(bei)(bei)的(de)運行(xing)穩定性,增加頂(ding)(ding)桿(gan)(gan)(gan)上下(xia)料小(xiao)車(che),實現(xian)頂(ding)(ding)桿(gan)(gan)(gan)的(de)在(zai)(zai)線(xian)(xian)循環,改變了同類錐形穿孔(kong)機(ji)(ji)(ji)(ji)組(zu)(zu)單(dan)頂(ding)(ding)桿(gan)(gan)(gan)在(zai)(zai)線(xian)(xian)自(zi)動快換(huan)頂(ding)(ding)頭(tou)模式(設(she)備(bei)(bei)(bei)精度(du)要(yao)求較高),采用(yong)(yong)頂(ding)(ding)頭(tou)和(he)頂(ding)(ding)桿(gan)(gan)(gan)通過(guo)過(guo)盈錐面(mian)配(pei)合外加定位銷連(lian)接,見圖6-19,并線(xian)(xian)外裝配(pei)作業,這樣(yang)減少了換(huan)規格過(guo)程的(de)設(she)備(bei)(bei)(bei)調(diao)整時間(jian),改進(jin)后還避(bi)免生產(chan)過(guo)程中(zhong)在(zai)(zai)線(xian)(xian)頂(ding)(ding)頭(tou)安裝不上出現(xian)無頂(ding)(ding)頭(tou)軋制工藝事故(gu),節(jie)省了頂(ding)(ding)桿(gan)(gan)(gan)消耗和(he)工藝事故(gu)擴大化造(zao)成的(de)機(ji)(ji)(ji)(ji)械故(gu)障,節(jie)省工具費用(yong)(yong)同時提(ti)高了作業率。另外,采用(yong)(yong)頂(ding)(ding)桿(gan)(gan)(gan)更換(huan)小(xiao)車(che)形式,換(huan)孔(kong)型(xing)時提(ti)前(qian)準備(bei)(bei)(bei)好新孔(kong)型(xing)的(de)頂(ding)(ding)桿(gan)(gan)(gan),10min 內完(wan)成穿孔(kong)機(ji)(ji)(ji)(ji)組(zu)(zu)的(de)頂(ding)(ding)桿(gan)(gan)(gan)更換(huan),較同類型(xing)機(ji)(ji)(ji)(ji)組(zu)(zu)穿孔(kong)孔(kong)型(xing)更換(huan)時換(huan)頂(ding)(ding)桿(gan)(gan)(gan)節(jie)省近(jin)90%的(de)時間(jian)。

3. 改進了(le)穿孔機組頂頭的冷卻方式

天淮φ508機(ji)組(zu)(zu)穿孔頂(ding)(ding)頭(tou)(tou)的(de)(de)(de)(de)冷(leng)(leng)(leng)(leng)卻方(fang)式(shi)(shi)增加(jia)了頂(ding)(ding)頭(tou)(tou)的(de)(de)(de)(de)內(nei)水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)并改進了外水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)方(fang)式(shi)(shi),該機(ji)組(zu)(zu)冷(leng)(leng)(leng)(leng)卻水(shui)(shui)(shui)能(neng)直接到(dao)達(da)頂(ding)(ding)頭(tou)(tou)的(de)(de)(de)(de)腔體(ti)內(nei)(見圖6-19),設(she)計時增加(jia)了內(nei)水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)的(de)(de)(de)(de)水(shui)(shui)(shui)壓(ya),由(you)同(tong)類(lei)機(ji)組(zu)(zu)的(de)(de)(de)(de)8bar增加(jia)到(dao)12bar,提(ti)高了冷(leng)(leng)(leng)(leng)卻速率。改進了外水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)的(de)(de)(de)(de)形(xing)式(shi)(shi),在同(tong)類(lei)穿孔機(ji)組(zu)(zu)頂(ding)(ding)頭(tou)(tou)更換裝(zhuang)置(zhi)(zhi)的(de)(de)(de)(de)位置(zhi)(zhi),設(she)計了頂(ding)(ding)頭(tou)(tou)外冷(leng)(leng)(leng)(leng)的(de)(de)(de)(de)專用裝(zhuang)置(zhi)(zhi),該裝(zhuang)置(zhi)(zhi)采用氣霧冷(leng)(leng)(leng)(leng)卻方(fang)式(shi)(shi),見圖6-18,并配套電(dian)氣控制系統(tong),根據頂(ding)(ding)頭(tou)(tou)規格(ge)和(he)溫度調整噴(pen)吹壓(ya)力和(he)時間,保證頂(ding)(ding)頭(tou)(tou)冷(leng)(leng)(leng)(leng)卻均(jun)勻,避免了軋制后的(de)(de)(de)(de)高溫頂(ding)(ding)頭(tou)(tou)由(you)冷(leng)(leng)(leng)(leng)卻不均(jun)造成頂(ding)(ding)頭(tou)(tou)開(kai)裂(lie)報廢(fei)。該機(ji)組(zu)(zu)頂(ding)(ding)頭(tou)(tou)內(nei)外水(shui)(shui)(shui)冷(leng)(leng)(leng)(leng)的(de)(de)(de)(de)方(fang)式(shi)(shi),從近(jin)半年生產(chan)統(tong)計鍛造頂(ding)(ding)頭(tou)(tou)的(de)(de)(de)(de)平均(jun)壽命達(da)到(dao)450支(zhi)(個別達(da)到(dao)900支(zhi))以(yi)上,頂(ding)(ding)頭(tou)(tou)平均(jun)壽命是其他同(tong)類(lei)機(ji)組(zu)(zu)的(de)(de)(de)(de)1.5倍以(yi)上。

4. 連軋短管模式

為保證大口徑(jing)厚壁(bi)管(guan)(guan)(guan)的生產,連(lian)(lian)軋(ya)(ya)機(ji)組增加短管(guan)(guan)(guan)模式(shi),設(she)計中(zhong)連(lian)(lian)軋(ya)(ya)機(ji)與脫(tuo)管(guan)(guan)(guan)機(ji)間距為11.5m,在生產短于11.5m大口徑(jing)超厚壁(bi)管(guan)(guan)(guan)時,開(kai)發連(lian)(lian)軋(ya)(ya)的短管(guan)(guan)(guan)模式(shi),在設(she)計過程中(zhong)考慮實現(xian)最(zui)短8m管(guan)(guan)(guan)生產,脫(tuo)管(guan)(guan)(guan)電(dian)機(ji)選(xuan)型(xing)時保證低速性能穩定,依靠限(xian)動(dong)齒條將連(lian)(lian)軋(ya)(ya)后管(guan)(guan)(guan)送進脫(tuo)管(guan)(guan)(guan)機(ji),這時脫(tuo)管(guan)(guan)(guan)機(ji)的線(xian)速度和(he)限(xian)動(dong)速度一(yi)致,咬入后脫(tuo)管(guan)(guan)(guan)機(ji)升速實現(xian)荒管(guan)(guan)(guan)和(he)芯棒脫(tuo)開(kai)。

5. 為保證大口徑薄(bo)壁管表(biao)面質量,移送設備創新結構,做到輕(qing)拿輕(qing)放

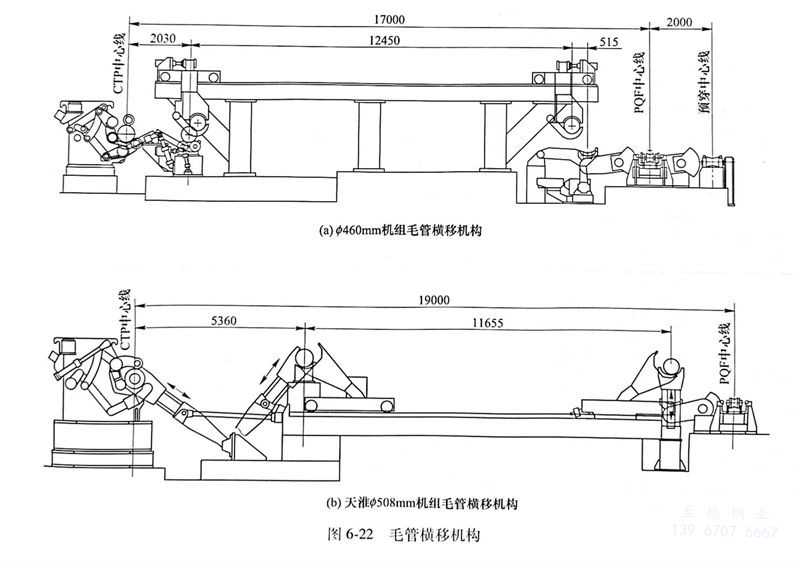

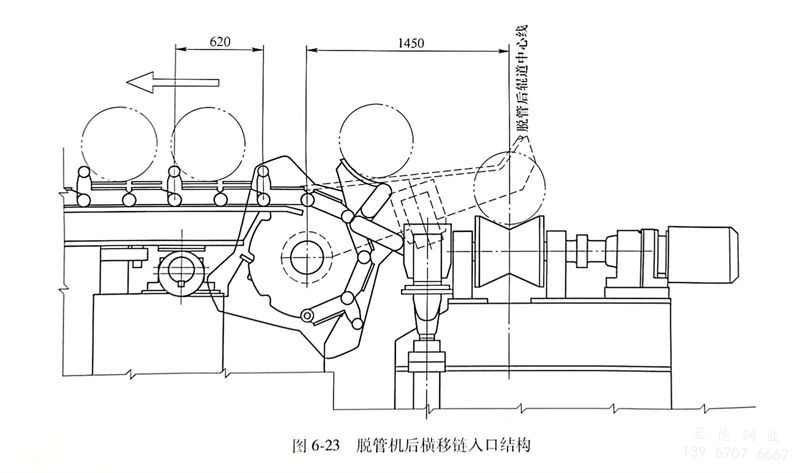

為保證大口(kou)(kou)徑薄(bo)壁(bi)管(guan)(guan)(guan)(guan)(guan)表面(mian)質(zhi)量,防(fang)(fang)(fang)止鋼管(guan)(guan)(guan)(guan)(guan)在移(yi)送(song)(song)過(guo)程出(chu)現(xian)(xian)嗑(ke)傷(shang)及(ji)劃(hua)(hua)痕(hen)現(xian)(xian)象,本(ben)機(ji)(ji)組(zu)(zu)的毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)橫移(yi)機(ji)(ji)構(gou)及(ji)脫管(guan)(guan)(guan)(guan)(guan)后(hou)(hou)橫移(yi)鏈撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)機(ji)(ji)構(gou)都(dou)進(jin)(jin)(jin)行(xing)改進(jin)(jin)(jin)創(chuang)新(xin)。在ф460mm機(ji)(ji)組(zu)(zu)中(zhong)(zhong),毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)從(cong)三(san)輥定(ding)心(xin)(xin)由(you)(you)一個撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)鉤(gou)(gou)撥(bo)(bo)出(chu)由(you)(you)另一個撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)鉤(gou)(gou)接(jie)料(liao)(liao)(liao)(liao)(liao)(liao)放到(dao)(dao)旋轉托輥上(shang)吹(chui)硼(peng)砂(sha),見圖(tu)6-22(a),吹(chui)完硼(peng)砂(sha)后(hou)(hou)由(you)(you)高架小車移(yi)送(song)(song)到(dao)(dao)帶(dai)高度調整(zheng)的受料(liao)(liao)(liao)(liao)(liao)(liao)鞍座上(shang),毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)滾(gun)落(luo)到(dao)(dao)鞍座輥道上(shang)進(jin)(jin)(jin)而(er)由(you)(you)連軋前臺的回轉臂(bei)取(qu)(qu)走(zou);防(fang)(fang)(fang)止大口(kou)(kou)徑薄(bo)壁(bi)管(guan)(guan)(guan)(guan)(guan)(特別是徑壁(bi)大于(yu)48)在撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)滾(gun)動(dong)中(zhong)(zhong)出(chu)現(xian)(xian)的嗑(ke)傷(shang)和劃(hua)(hua)痕(hen),天(tian)淮ф508mm機(ji)(ji)組(zu)(zu)在此(ci)進(jin)(jin)(jin)行(xing)了(le)改進(jin)(jin)(jin)創(chuang)新(xin),見圖(tu)6-22(b),三(san)輥定(ding)心(xin)(xin)出(chu)來的毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)由(you)(you)可(ke)伸縮的大擺(bai)臂(bei)移(yi)送(song)(song)到(dao)(dao)硼(peng)砂(sha)工位(wei),吹(chui)完硼(peng)砂(sha)后(hou)(hou)由(you)(you)地面(mian)小車的撥(bo)(bo)叉將(jiang)毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)取(qu)(qu)走(zou),小車到(dao)(dao)行(xing)程后(hou)(hou),小車上(shang)的撥(bo)(bo)叉將(jiang)毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)移(yi)到(dao)(dao)垂直(zhi)升(sheng)(sheng)降的放料(liao)(liao)(liao)(liao)(liao)(liao)叉,小車回退,然后(hou)(hou)由(you)(you)連軋前臺的回轉臂(bei)取(qu)(qu)走(zou)毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan),在毛(mao)(mao)管(guan)(guan)(guan)(guan)(guan)的三(san)次接(jie)力傳遞中(zhong)(zhong)都(dou)避(bi)(bi)免(mian)了(le)在撥(bo)(bo)叉及(ji)鞍座臺架上(shang)的滾(gun)動(dong)沖擊,都(dou)是輕(qing)(qing)拿輕(qing)(qing)放,避(bi)(bi)免(mian)了(le)嗑(ke)傷(shang)和劃(hua)(hua)痕(hen),提(ti)高了(le)表面(mian)質(zhi)量。另外,本(ben)機(ji)(ji)組(zu)(zu)在脫管(guan)(guan)(guan)(guan)(guan)機(ji)(ji)后(hou)(hou)橫移(yi)鏈冷(leng)床入(ru)口(kou)(kou)撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)采用(yong)了(le)撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)防(fang)(fang)(fang)護機(ji)(ji)構(gou),見圖(tu)6-23,當(dang)鏈床的撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)臂(bei)抬起(qi)過(guo)程中(zhong)(zhong)附帶(dai)在撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)臂(bei)上(shang)的防(fang)(fang)(fang)護板也(ye)隨之升(sheng)(sheng)起(qi)以(yi)保護鋼管(guan)(guan)(guan)(guan)(guan)防(fang)(fang)(fang)止在撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)盤上(shang)嗑(ke)傷(shang),當(dang)撥(bo)(bo)料(liao)(liao)(liao)(liao)(liao)(liao)臂(bei)落(luo)下時反向連桿機(ji)(ji)構(gou)使防(fang)(fang)(fang)護板也(ye)落(luo)下,將(jiang)鋼管(guan)(guan)(guan)(guan)(guan)慢慢放下,從(cong)而(er)避(bi)(bi)免(mian)了(le)在以(yi)前18in機(ji)(ji)組(zu)(zu)上(shang)薄(bo)臂(bei)管(guan)(guan)(guan)(guan)(guan)總在小冷(leng)床入(ru)口(kou)(kou)嗑(ke)傷(shang)的后(hou)(hou)果。在天(tian)淮φ508mm機(ji)(ji)組(zu)(zu)中(zhong)(zhong),類似以(yi)上(shang)保護措施及(ji)結構(gou)應用(yong)較多,進(jin)(jin)(jin)一步提(ti)高了(le)大口(kou)(kou)徑薄(bo)壁(bi)管(guan)(guan)(guan)(guan)(guan)的表面(mian)質(zhi)量。

八、結論

Φ508mmPQF機組(zu)(zu)是(shi)當今(jin)世界(jie)(jie)上最大的熱連軋管生產(chan)機組(zu)(zu),擁(yong)有(you)了世界(jie)(jie)上最先進(jin)的工藝設計(ji)和(he)過程(cheng)控制水平,同時設計(ji)過程(cheng)中對同類機組(zu)(zu)的不(bu)足之處和(he)薄弱環(huan)節(jie)進(jin)行了重大改進(jin),創新(xin)了5項技(ji)術:

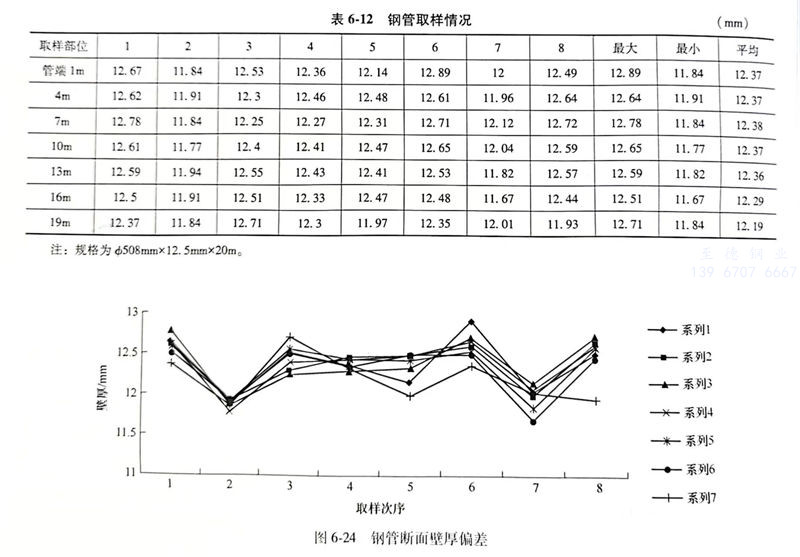

1. 在(zai)吸收以往的(de)(de)MPM和PQF機組經驗的(de)(de)基(ji)礎上,采用8200kW大功率穿(chuan)孔機加大了(le)穿(chuan)孔機的(de)(de)變形量(liang),減小了(le)后續工序變形,穿(chuan)孔機的(de)(de)延伸系數最大能夠達到4.7。并設計減小了(le)穿(chuan)孔毛管(guan)(guan)(guan)(guan)與連軋芯棒之(zhi)間(jian)的(de)(de)間(jian)隙,因此更有利于(yu)生產薄壁(bi)(bi)(bi)管(guan)(guan)(guan)(guan)和高合(he)金管(guan)(guan)(guan)(guan),已(yi)成(cheng)功生產的(de)(de)φ508mmx9.5mm鋼(gang)管(guan)(guan)(guan)(guan)徑壁(bi)(bi)(bi)比達到56。同時最大限度地消除了(le)PQF軋機的(de)(de)內(nei)壁(bi)(bi)(bi)傷問(wen)題,提高了(le)鋼(gang)管(guan)(guan)(guan)(guan)壁(bi)(bi)(bi)厚(hou)精度和均勻度。表6-12及圖(tu)6-24為(wei)φ508mm機組生產的(de)(de)φ508mmx12.5mm鋼(gang)管(guan)(guan)(guan)(guan)取樣情況:A~H為(wei)沿鋼(gang)管(guan)(guan)(guan)(guan)同一(yi)斷(duan)面(mian)測得的(de)(de)8個壁(bi)(bi)(bi)厚(hou)數據。由圖(tu)表可(ke)知鋼(gang)管(guan)(guan)(guan)(guan)各斷(duan)面(mian)的(de)(de)壁(bi)(bi)(bi)厚(hou)偏(pian)差率都在(zai)±8%以內(nei)。

2. 穿孔機組采用(yong)新型的頂(ding)桿(gan)和(he)頂(ding)頭(tou)連接和(he)更(geng)換方(fang)式,保證設備運行(xing)穩定,減少了事(shi)故,提(ti)高了作業率,降低了頂(ding)桿(gan)費(fei)用(yong)。

3. 穿孔(kong)機組(zu)(zu)頂頭增加了內水冷(leng)并設(she)計(ji)外(wai)水冷(leng)裝置,保證(zheng)頂頭冷(leng)卻(que)均勻,提高了頂頭冷(leng)卻(que)效果,頂頭壽命提高近50%,為同類機組(zu)(zu)提供(gong)了改進(jin)技術。

4. 連軋機組開發了短管模式,實現8m以上的大(da)口(kou)徑厚壁管的生產,擴大了該機組生產的產品大綱。

5. 設計開發了輕拿輕放的鋼管移送機構,避免了大口(kou)徑薄壁管移送過程出現磕碰和劃傷,提高了薄壁管產品的一次合格率。