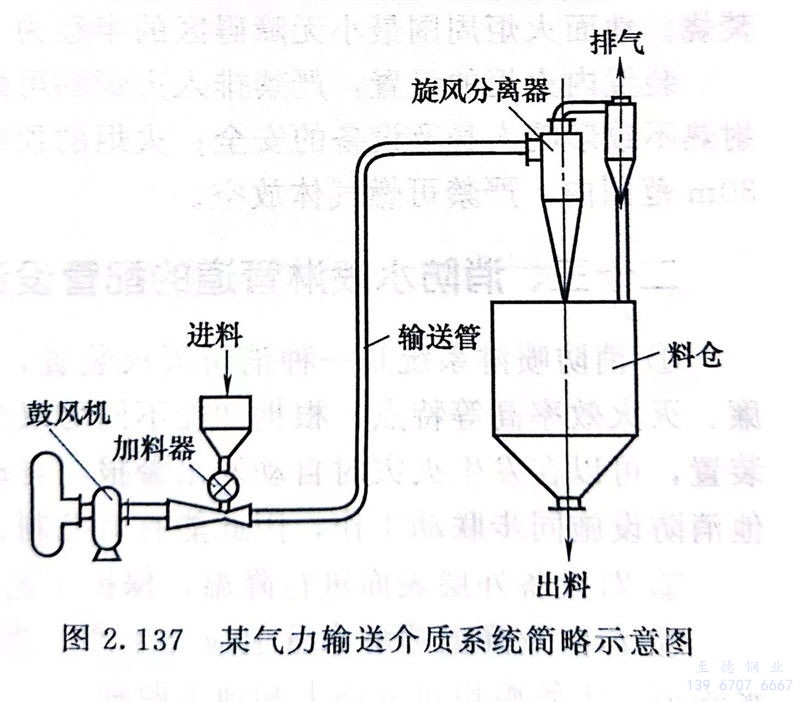

氣(qi)(qi)(qi)(qi)力輸(shu)送(song)(song)(song)(song)(song)(又稱氣(qi)(qi)(qi)(qi)流(liu)輸(shu)送(song)(song)(song)(song)(song)),即(ji)利用(yong)氣(qi)(qi)(qi)(qi)流(liu)的(de)(de)能量,在密(mi)閉管道內沿(yan)氣(qi)(qi)(qi)(qi)流(liu)方(fang)向(xiang)輸(shu)送(song)(song)(song)(song)(song)顆(ke)粒狀物(wu)料,是(shi)流(liu)態化(hua)技術的(de)(de)一種具體(ti)應(ying)用(yong)。氣(qi)(qi)(qi)(qi)流(liu)輸(shu)送(song)(song)(song)(song)(song)裝置(zhi)(圖2.137)的(de)(de)結(jie)構簡(jian)單,操(cao)(cao)作(zuo)方(fang)便,可作(zuo)水平的(de)(de)、垂(chui)直的(de)(de)或傾斜方(fang)向(xiang)的(de)(de)輸(shu)送(song)(song)(song)(song)(song),在輸(shu)送(song)(song)(song)(song)(song)過程中還可同時進行(xing)物(wu)料的(de)(de)加熱(re)、冷卻、輸(shu)送(song)(song)(song)(song)(song)和氣(qi)(qi)(qi)(qi)流(liu)分(fen)級(ji)等物(wu)理操(cao)(cao)作(zuo)或某些化(hua)學操(cao)(cao)作(zuo)。氣(qi)(qi)(qi)(qi)力輸(shu)送(song)(song)(song)(song)(song)裝置(zhi)屬(shu)于密(mi)相中壓(ya)氣(qi)(qi)(qi)(qi)力輸(shu)送(song)(song)(song)(song)(song),適用(yong)于不(bu)易破碎顆(ke)粒、粉料氣(qi)(qi)(qi)(qi)力輸(shu)送(song)(song)(song)(song)(song)、物(wu)料的(de)(de)輸(shu)送(song)(song)(song)(song)(song),廣泛(fan)應(ying)用(yong)于化(hua)工、醫藥、糧食的(de)(de)行(xing)業。

①. 氣(qi)力輸(shu)送(song)介質管道的布置(zhi)應(ying)使管道短,彎頭數(shu)量少。水平管段不(bu)宜過長,且(qie)管道不(bu)得(de)有死角(jiao)和“袋(dai)形”出現。

②. 氣力輸送(song)介質管(guan)道(dao)的布置應(ying)采用大曲(qu)率(lv)半徑的彎管(guan),彎管(guan)的曲(qu)率(lv)半徑應(ying)根據輸送(song)方(fang)(fang)式、物料的特性、工藝要求(qiu)和流(liu)動(dong)方(fang)(fang)向確定,且應(ying)滿足PID或風送(song)系(xi)統制造商的要求(qiu)。

③. 在供料(liao)器后(hou)的氣力輸送介質管(guan)道應(ying)設置一段直管(guan)段,直管(guan)段的長度應(ying)滿足(zu)PID或風送系統制造商的要求。

④. 氣力輸送管(guan)道的水(shui)(shui)平走(zou)向直(zhi)管(guan)段(duan)不宜(yi)太長。當水(shui)(shui)平直(zhi)管(guan)段(duan)較(jiao)長時,應在水(shui)(shui)平管(guan)段(duan)中間(jian)加一段(duan)垂直(zhi)管(guan)段(duan),然(ran)后管(guan)道繼(ji)續水(shui)(shui)平走(zou)向。

⑤. 氣力輸送介質管道應有可靠的靜電接(jie)地設(she)施,管道上的法蘭宜跨接(jie)。

⑥. 氣力輸送管(guan)(guan)(guan)道(dao)應滿足(zu)操作、安裝、檢修、事(shi)故處理的要(yao)求(qiu),在垂直管(guan)(guan)(guan)道(dao)的下部或(huo)水(shui)平(ping)管(guan)(guan)(guan)道(dao)的適當部位應設置拆卸短管(guan)(guan)(guan),供管(guan)(guan)(guan)道(dao)堵(du)塞時清料使用。

⑦. 對氣力輸送管(guan)道系統的管(guan)道,必須設置牢固(gu)的管(guan)支(zhi)架。設計時(shi)(shi)不僅要考(kao)慮(lv)支(zhi)承其全部重(zhong)量(liang),同時(shi)(shi)還應考(kao)慮(lv)其振動因素。

⑧. 氣力輸送系(xi)(xi)統(tong)應(ying)有粉塵防爆措(cuo)施,對風送系(xi)(xi)統(tong)內各種設(she)備的排(pai)氣口,都應(ying)接到(dao)除塵系(xi)(xi)統(tong),不得有粉塵在裝置內泄漏。

⑨. 所有(you)氣流輸送管(guan)道的(de)端(duan)部(bu)焊接前必須采用機(ji)械(xie)加工。所有(you)管(guan)道端(duan)部(bu)的(de)坡口應打磨光滑、無毛(mao)刺、銳角。