輥式冷彎成型是以金屬薄板或帶卷為原料,并通過多架裝配了具有一定形狀的成型輥對坯料逐架次進行彎曲變形,從而得到均一最面的產品的塑性加工方法。

一般每架(jia)成型機裝有一對或多對成型輥(gun),每列成型機組(zu)由兩架(jia)以(yi)上的成型機組(zu)線。在(zai)輥(gun)式冷彎(wan)成型過程(cheng)中(zhong)只有彎(wan)曲(qu)變形(xing)(xing)。除坯料彎(wan)曲(qu)角局部有輕微(wei)減薄(bo)外(wai),變形(xing)(xing)材料的厚度(du)(du)在(zai)成型過程(cheng)中(zhong)保持(chi)不(bu)變。這種加工(gong)方法特(te)別適合于外(wai)形(xing)(xing)縱長(chang)、批量較大的高精度(du)(du)產(chan)品(pin)的加工(gong),此(ci)外(wai),在(zai)輥(gun)式冷彎(wan)成型過程(cheng)中(zhong),可以(yi)很容易地將沖(chong)裁、打孔、壓印、縱彎(wan)等輔助加工(gong)引入進來。

輥式冷彎成(cheng)(cheng)(cheng)型(xing)(xing)工(gong)(gong)藝(yi)可分為四種,即單(dan)張(或(huo)單(dan)件)成(cheng)(cheng)(cheng)型(xing)(xing)工(gong)(gong)藝(yi)、成(cheng)(cheng)(cheng)卷成(cheng)(cheng)(cheng)型(xing)(xing)工(gong)(gong)藝(yi)、連續成(cheng)(cheng)(cheng)型(xing)(xing)工(gong)(gong)藝(yi)和聯合(he)加(jia)工(gong)(gong)工(gong)(gong)藝(yi)。每(mei)一種工(gong)(gong)藝(yi)都可分為3個階段(duan),即成(cheng)(cheng)(cheng)型(xing)(xing)前坯料準備(bei)階段(duan)、成(cheng)(cheng)(cheng)型(xing)(xing)加(jia)工(gong)(gong)階段(duan)、型(xing)(xing)材(cai)精整階段(duan)。

單張成(cheng)(cheng)(cheng)型工(gong)藝(yi)(yi)(yi)就是預定尺(chi)坯料的成(cheng)(cheng)(cheng)型方法(fa)。這種(zhong)方法(fa)在坯料成(cheng)(cheng)(cheng)型之前將坯料切(qie)(qie)成(cheng)(cheng)(cheng)定尺(chi)長度,然后(hou)(hou)用送料輥將坯料送進成(cheng)(cheng)(cheng)型輥,成(cheng)(cheng)(cheng)型后(hou)(hou)的型材不必經剪切(qie)(qie)即可收集入庫。采(cai)用這種(zhong)成(cheng)(cheng)(cheng)型工(gong)藝(yi)(yi)(yi)的成(cheng)(cheng)(cheng)型輥的速(su)度一般在15~75m/min.這種(zhong)工(gong)藝(yi)(yi)(yi)主(zhu)要(yao)應用于小批量(liang)、成(cheng)(cheng)(cheng)型后(hou)(hou)型材鋸切(qie)(qie)比較(jiao)困難的情況(kuang)下。采(cai)用單張成(cheng)(cheng)(cheng)型工(gong)藝(yi)(yi)(yi)成(cheng)(cheng)(cheng)型機組的設備較(jiao)簡(jian)單、工(gong)具費(fei)用少、投資低。但(dan)用這種(zhong)生產(chan)工(gong)藝(yi)(yi)(yi)得(de)到(dao)的型材邊部縱向拉伸(shen)較(jiao)大,因(yin)而(er)只有利用側立輥才(cai)能得(de)到(dao)比較(jiao)精(jing)確的產(chan)品形。

成(cheng)(cheng)卷(juan)成(cheng)(cheng)型(xing)(xing)工(gong)藝(yi)和連(lian)(lian)續成(cheng)(cheng)型(xing)(xing)工(gong)藝(yi)基本相(xiang)(xiang)同(tong),所不(bu)同(tong)的(de)是連(lian)(lian)續成(cheng)(cheng)型(xing)(xing)時前(qian)一卷(juan)帶(dai)材(cai)的(de)尾部(bu)與后一卷(juan)帶(dai)材(cai)的(de)頭(tou)(tou)部(bu)經(jing)過齊對焊(han),使(shi)坯料(liao)帶(dai)材(cai)連(lian)(lian)續不(bu)斷地(di)進(jin)(jin)人(ren)成(cheng)(cheng)型(xing)(xing)機進(jin)(jin)行成(cheng)(cheng)型(xing)(xing)。而成(cheng)(cheng)卷(juan)成(cheng)(cheng)型(xing)(xing)時帶(dai)卷(juan)頭(tou)(tou)尾不(bu)對焊(han),進(jin)(jin)行單卷(juan)供料(liao)成(cheng)(cheng)型(xing)(xing)。與單張(zhang)成(cheng)(cheng)型(xing)(xing)工(gong)藝(yi)相(xiang)(xiang)比,這兩種(zhong)成(cheng)(cheng)型(xing)(xing)工(gong)藝(yi)更加(jia)高效(xiao)、高產、通用。這兩種(zhong)成(cheng)(cheng)型(xing)(xing)工(gong)藝(yi)的(de)主要優點是:

①. 帶卷成本低(di)、切損(sun)少(shao),因而降低(di)了(le)材料總成本。

②. 由于需要(yao)(yao)的成型機架數少(shao)且不(bu)需要(yao)(yao)額外的導衛(wei)裝置,因而工具成本低。

③. 可以加工形狀比(bi)單(dan)張成型工藝更復雜(za)的型材(cai)。

④. 型材的頭(tou)尾部扭曲及張開度(du)減小(xiao)。

⑤. 由于操作(zuo)幾乎是連(lian)續的,因而生產率得到提高(gao)。

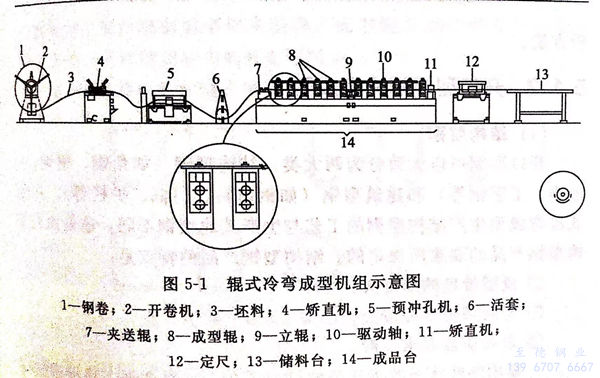

但(dan)這兩(liang)(liang)種(zhong)成(cheng)(cheng)型工藝(yi)需(xu)要開(kai)卷機(ji)、活套器、對焊機(ji)、定尺飛(fei)鋸或飛(fei)剪等輔助設備(bei),因而其機(ji)組(zu)設備(bei)投資(zi)較大(da)、占地較大(da)。成(cheng)(cheng)型機(ji)組(zu)的成(cheng)(cheng)型速度一般為(wei)30~90m/min.目前(qian)投產的絕大(da)多數輥式冷(leng)彎成(cheng)(cheng)型機(ji)組(zu)均(jun)是采用這兩(liang)(liang)種(zhong)工藝(yi),因此后面將以這兩(liang)(liang)種(zhong)成(cheng)(cheng)型工藝(yi)為(wei)例進行重點闡述,圖(tu)5-1給出了其工藝(yi)流(liu)程示(shi)意(yi)圖(tu)。

聯(lian)合(he)加(jia)工工藝用于加(jia)工具有特定要(yao)求的冷(leng)(leng)彎型(xing)(xing)(xing)鋼,如高(gao)(gao)強度冷(leng)(leng)彎型(xing)(xing)(xing)鋼、閉口焊(han)(han)接冷(leng)(leng)彎型(xing)(xing)(xing)鋼、熱處理(li)強化(hua)冷(leng)(leng)彎型(xing)(xing)(xing)鋼、周期波紋板沖孔冷(leng)(leng)彎型(xing)(xing)(xing)鋼,涂層冷(leng)(leng)彎型(xing)(xing)(xing)鋼等。聯(lian)合(he)加(jia)工成型(xing)(xing)(xing)機組的設備最(zui)(zui)復雜、投資最(zui)(zui)高(gao)(gao)。根(gen)據產品的要(yao)求這種(zhong)機組可包括如下(xia)設備:直縫(feng)焊(han)(han)機、對焊(han)(han)機、輥式沖孔機、輥式壓印(yin)機、涂層機、熱處理(li)設備等。

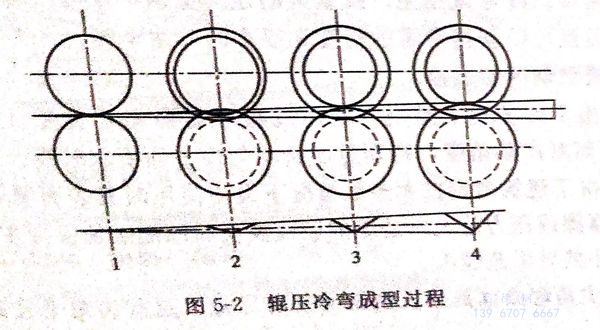

輥(gun)式冷彎(wan)成(cheng)(cheng)型(xing)(xing)(xing)是用一(yi)組(zu)(zu)(zu)成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)將帶(dai)材(cai)(cai)逐(zhu)漸(jian)壓彎(wan)成(cheng)(cheng)所需的(de)斷面(mian)型(xing)(xing)(xing)材(cai)(cai),現以冷彎(wan)角鋼(gang)為例,圖(tu)5-2是由4個(ge)機(ji)架組(zu)(zu)(zu)成(cheng)(cheng)的(de)輥(gun)式冷彎(wan)成(cheng)(cheng)型(xing)(xing)(xing)機(ji)組(zu)(zu)(zu),第一(yi)機(ji)架完成(cheng)(cheng)帶(dai)材(cai)(cai)的(de)平整和送進(jin)工作,第二(er)~第四(si)機(ji)架各承(cheng)擔(dan)一(yi)定的(de)壓彎(wan)成(cheng)(cheng)型(xing)(xing)(xing)任務,使帶(dai)材(cai)(cai)通過后被彎(wan)曲壓制成(cheng)(cheng)角型(xing)(xing)(xing)材(cai)(cai)。每一(yi)對成(cheng)(cheng)型(xing)(xing)(xing)輥(gun)所分擔(dan)的(de)彎(wan)曲變形量,決定了該機(ji)架孔型(xing)(xing)(xing)設計的(de)基(ji)本尺(chi)寸。不(bu)過至今的(de)孔型(xing)(xing)(xing)設計主要還是依靠經驗的(de)積累,尚(shang)缺乏理(li)論解析方(fang)法(fa)。