一、非(fei)金(jin)屬軟墊片尺寸公差

1. 平面和突面法蘭(lan)用墊(dian)片(pian)

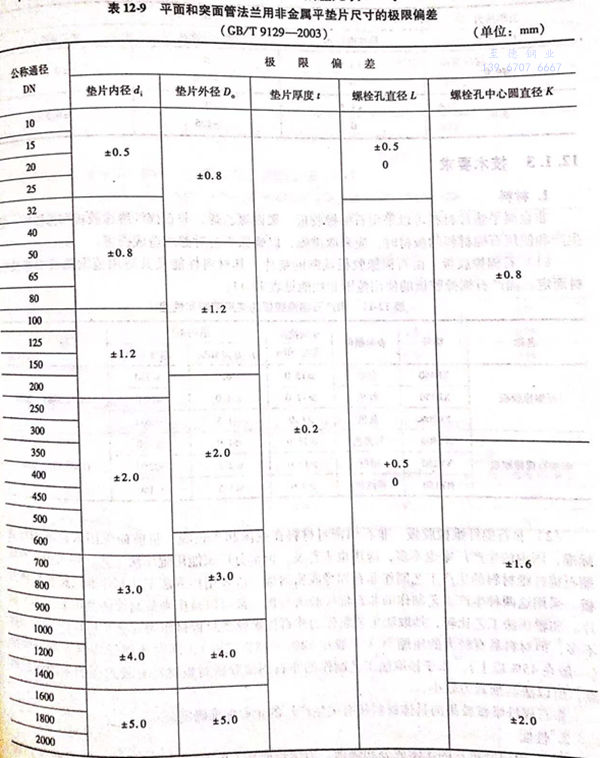

平面(mian)和突面(mian)管(guan)法(fa)蘭用非金(jin)屬平墊片尺寸(cun)的極限(xian)偏差(cha)見表12-9。

2. 凹凸面和榫槽面法蘭(lan)用墊片(pian)

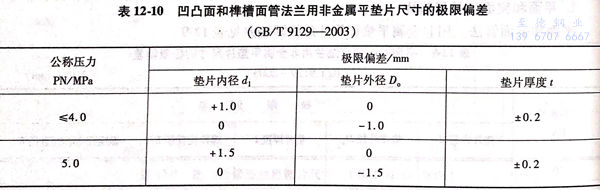

凹凸面(mian)和榫槽面(mian)管法蘭(lan)用非金屬平墊片尺寸的極限(xian)偏差見表12-10。

二、非金屬軟墊(dian)片技術要求

1. 材(cai)料

非(fei)金屬平墊片材(cai)料(liao)可以(yi)采用(yong)石(shi)棉(mian)橡膠板、聚(ju)四(si)氟(fu)乙烯、非(fei)石(shi)棉(mian)纖維橡膠板和橡膠等。但生產和使(shi)用(yong)石(shi)棉(mian)材(cai)料(liao)的板材(cai)時,應采取措施,以(yi)確保不會對健康造(zao)成損害。

a. 石棉橡膠板

由石棉(mian)橡膠板裁制(zhi)的墊片,其(qi)材(cai)料性能及其(qi)適用(yong)范圍隨石棉(mian)橡膠板材(cai)而定。國產石棉(mian)橡膠板的使用(yong)范圍和(he)性能見表(biao)12-11。

b. 非(fei)石棉纖維(wei)橡膠板

非(fei)(fei)石(shi)棉(mian)(mian)(mian)密封(feng)材(cai)(cai)(cai)料在我國(guo)起(qi)步較晚(wan),目前(qian)尚無國(guo)家(jia)標準和(he)行業標準,國(guo)內的生產(chan)廠家(jia)也(ye)不多(duo),應用(yong)(yong)(yong)(yong)也(ye)未(wei)普及(ji),但(dan)部(bu)分廠家(jia)能(neng)用(yong)(yong)(yong)(yong)輥(gun)壓(ya)法(fa)(fa)工(gong)(gong)藝,即(ji)采用(yong)(yong)(yong)(yong)生產(chan)壓(ya)縮(suo)石(shi)棉(mian)(mian)(mian)纖(xian)維材(cai)(cai)(cai)料的生產(chan)工(gong)(gong)藝制(zhi)作(zuo)(zuo)非(fei)(fei)石(shi)棉(mian)(mian)(mian)橡(xiang)(xiang)膠(jiao)(jiao)密封(feng)板(ban),以(yi)及(ji)用(yong)(yong)(yong)(yong)抄取法(fa)(fa)工(gong)(gong)藝制(zhi)作(zuo)(zuo)非(fei)(fei)石(shi)棉(mian)(mian)(mian)橡(xiang)(xiang)膠(jiao)(jiao)密封(feng)板(ban)。采用(yong)(yong)(yong)(yong)這(zhe)兩(liang)種生產(chan)工(gong)(gong)藝制(zhi)作(zuo)(zuo)的非(fei)(fei)石(shi)棉(mian)(mian)(mian)橡(xiang)(xiang)膠(jiao)(jiao)密封(feng)板(ban),都可以(yi)被(bei)用(yong)(yong)(yong)(yong)來裁制(zhi)管法(fa)(fa)蘭(lan)用(yong)(yong)(yong)(yong)非(fei)(fei)金屬平(ping)墊(dian)片。和(he)輥(gun)壓(ya)法(fa)(fa)工(gong)(gong)藝比(bi)較,抄取法(fa)(fa)工(gong)(gong)藝制(zhi)作(zuo)(zuo)的非(fei)(fei)石(shi)棉(mian)(mian)(mian)橡(xiang)(xiang)膠(jiao)(jiao)密封(feng)板(ban)材(cai)(cai)(cai)作(zuo)(zuo)為管法(fa)(fa)蘭(lan)墊(dian)片使用(yong)(yong)(yong)(yong)雖(sui)為數不多(duo),但(dan)材(cai)(cai)(cai)料具有(you)較大的壓(ya)縮(suo)率(lv)(一(yi)般(ban)在12%~18%之間),同時還(huan)能(neng)保持較大的回彈率(lv)(一(yi)般(ban)在45%以(yi)上)。由于抄取法(fa)(fa)工(gong)(gong)藝制(zhi)作(zuo)(zuo)的非(fei)(fei)石(shi)棉(mian)(mian)(mian)橡(xiang)(xiang)膠(jiao)(jiao)密封(feng)板(ban)材(cai)(cai)(cai)具有(you)較大壓(ya)縮(suo)率(lv)的性(xing)能(neng)特點,所以(yi)法(fa)(fa)蘭(lan)預(yu)緊力較小。

非石(shi)棉(mian)纖維橡膠(jiao)板的具(ju)體材料按有關生產廠的企業標準(zhun)確(que)定(ding)。

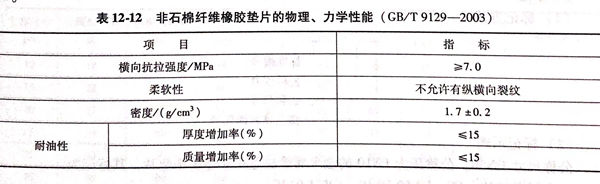

2. 性能

a. 石(shi)(shi)棉(mian)橡(xiang)膠墊片的化學(xue)成(cheng)分和(he)(he)物理(li)(li)、力學(xue)性能(neng)按GB/T 3985-2008《石(shi)(shi)棉(mian)橡(xiang)膠板》和(he)(he)GB/T 539-2008《耐油石(shi)(shi)棉(mian)橡(xiang)膠板》的規定;純聚四(si)氟乙烯墊片和(he)(he)橡(xiang)膠墊片的化學(xue)成(cheng)分和(he)(he)物理(li)(li)、力學(xue)性能(neng)應(ying)按有關材料(liao)標準的規定;非石(shi)(shi)棉(mian)纖維橡(xiang)膠墊片的物理(li)(li)、力學(xue)性能(neng)見表(biao)12-12。

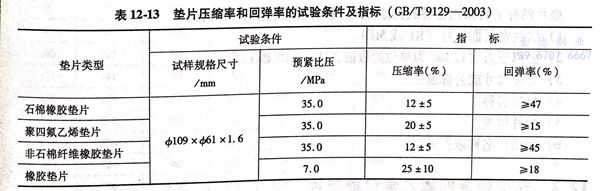

b. 墊片(pian)壓(ya)縮率和回彈(dan)率的試驗(yan)條(tiao)件及指標見表12-13。

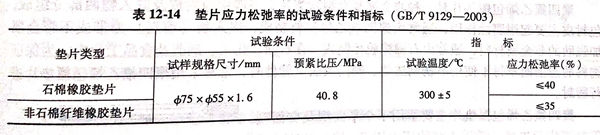

c. 墊片應力松弛率的試(shi)驗(yan)條件和指標見表 12-14。

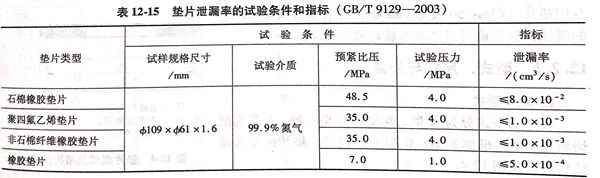

d. 墊片泄漏(lou)率的試驗條(tiao)件和(he)指標(biao)見(jian)表 12-15 。