空(kong)氣冷(leng)(leng)卻(que)(que)(que)(que)器(qi)(qi)(qi)(qi)(簡稱空(kong)冷(leng)(leng)器(qi)(qi)(qi)(qi))是(shi)以(yi)環(huan)境空(kong)氣作(zuo)為(wei)冷(leng)(leng)卻(que)(que)(que)(que)介(jie)質,冷(leng)(leng)卻(que)(que)(que)(que)高溫工(gong)藝(yi)流體的(de)(de)換(huan)熱(re)器(qi)(qi)(qi)(qi),也稱空(kong)氣冷(leng)(leng)卻(que)(que)(que)(que)式(shi)換(huan)熱(re)器(qi)(qi)(qi)(qi)。管內的(de)(de)熱(re)流體通(tong)(tong)過管壁和翅片與管外空(kong)氣進行換(huan)熱(re),所用的(de)(de)空(kong)氣通(tong)(tong)常由(you)通(tong)(tong)風(feng)機(ji)供給。空(kong)氣冷(leng)(leng)卻(que)(que)(que)(que)器(qi)(qi)(qi)(qi)可(ke)用于(yu)冷(leng)(leng)卻(que)(que)(que)(que)或冷(leng)(leng)凝(ning),廣泛應(ying)用于(yu):煉(lian)油(you)、石(shi)油(you)化工(gong)塔(ta)頂蒸(zheng)氣的(de)(de)冷(leng)(leng)凝(ning);回流油(you)、塔(ta)底油(you)的(de)(de)冷(leng)(leng)卻(que)(que)(que)(que);各種(zhong)反應(ying)生成物(wu)的(de)(de)冷(leng)(leng)卻(que)(que)(que)(que);循環(huan)氣體的(de)(de)冷(leng)(leng)卻(que)(que)(que)(que)和電站汽輪機(ji)排氣的(de)(de)冷(leng)(leng)凝(ning)。工(gong)作(zuo)壓(ya)力可(ke)達(da)69MPa。但耗(hao)電量、噪聲和占地(di)面積均大,冷(leng)(leng)卻(que)(que)(que)(que)效(xiao)果受氣候變化影響較大。空(kong)冷(leng)(leng)器(qi)(qi)(qi)(qi)標準(zhun)主(zhu)要有API 661《煉(lian)油(you)廠用通(tong)(tong)用空(kong)氣冷(leng)(leng)卻(que)(que)(que)(que)換(huan)熱(re)器(qi)(qi)(qi)(qi)》、ISO 13706《石(shi)油(you)、石(shi)化和天然氣工(gong)業風(feng)冷(leng)(leng)式(shi)換(huan)熱(re)器(qi)(qi)(qi)(qi)》、GB/T 15386《空(kong)冷(leng)(leng)式(shi)換(huan)熱(re)器(qi)(qi)(qi)(qi)》等。

1. 空氣(qi)冷(leng)卻器的結構

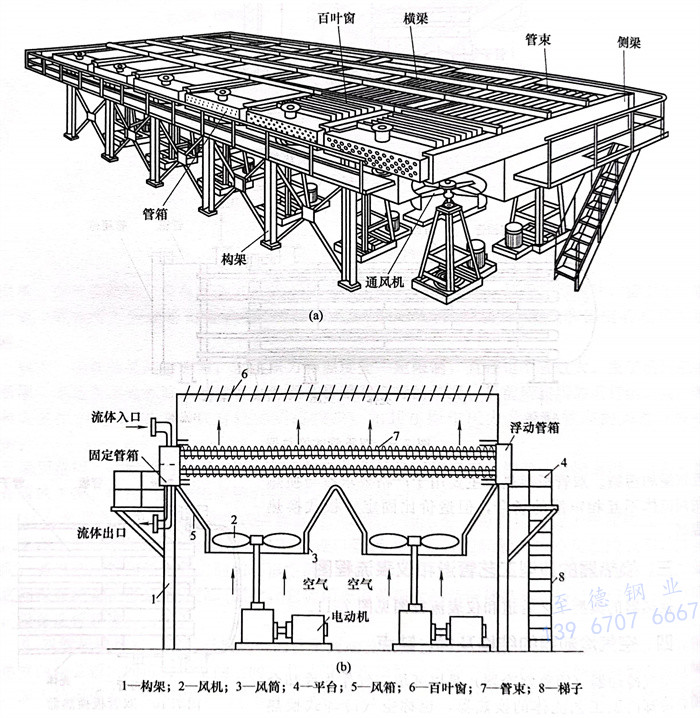

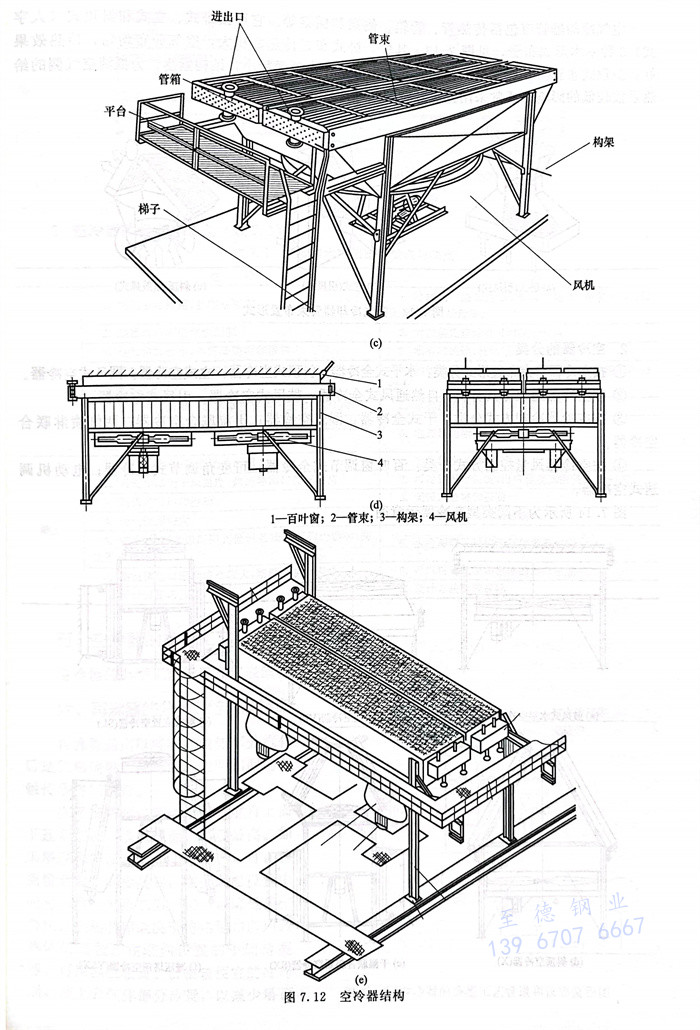

空氣(qi)冷卻(que)器主要由管束、通風機、構架及百葉窗等組成(cheng),如圖7.12所示。

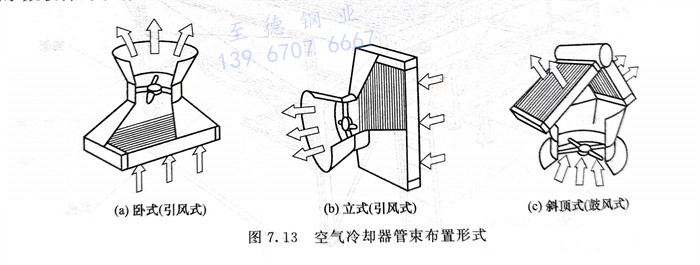

空(kong)氣冷卻器管束(shu)包括傳(chuan)(chuan)熱(re)管、管箱、側(ce)梁和橫梁等(deng)。它可按臥(wo)式(shi)、立式(shi)和斜頂式(shi)(人字式(shi))3種(zhong)基本形式(shi)布(bu)置(zhi)(zhi),見(jian)圖(tu)7.13。其中,臥(wo)式(shi)布(bu)置(zhi)(zhi)傳(chuan)(chuan)熱(re)面(mian)積(ji)大,空(kong)氣分布(bu)均勻,傳(chuan)(chuan)熱(re)效果好;斜頂式(shi)布(bu)置(zhi)(zhi)時,通風機安裝(zhuang)在人字中央(yang)空(kong)間,占(zhan)地面(mian)積(ji)小(xiao),結構緊湊。為抵消空(kong)氣側(ce)的給熱(re)系數較(jiao)低(di)的影(ying)響,通常采用光管外壁(bi)裝(zhuang)翅片的管子。

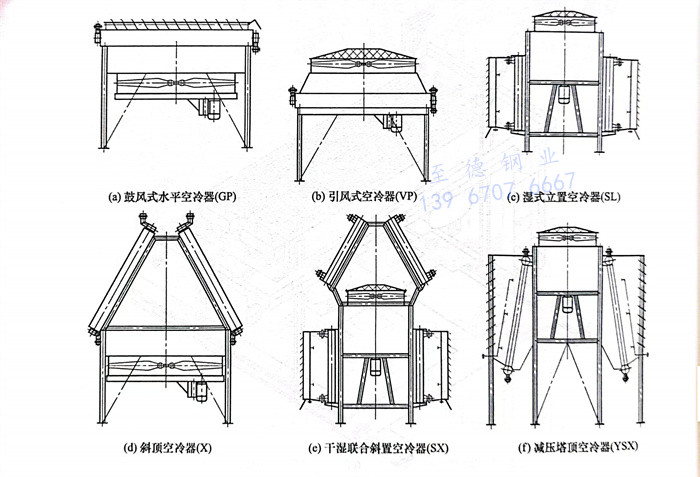

2. 空冷(leng)器的分類

①. 按空冷(leng)器(qi)管束布置形式分(fen)類:水平式全冷(leng)器(qi);斜頂式空冷(leng)器(qi);立式空冷(leng)器(qi);圓(yuan)環式空冷(leng)器(qi)。

②. 按空冷(leng)器通風(feng)方(fang)式分類:自然通風(feng)式全冷(leng)器;鼓風(feng)式空冷(leng)器;引風(feng)式空冷(leng)器。

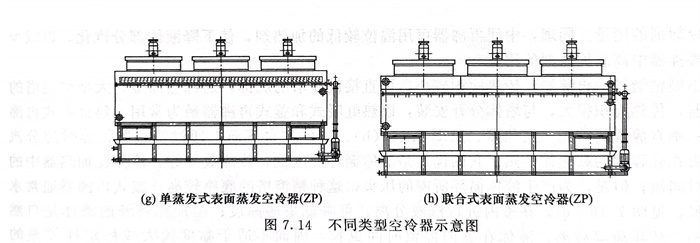

③. 按空冷(leng)(leng)器(qi)冷(leng)(leng)卻方式(shi)分(fen)類:干式(shi)全冷(leng)(leng)器(qi):濕式(shi)空冷(leng)(leng)器(qi);干濕聯合空冷(leng)(leng)器(qi);兩側(ce)噴淋(lin)聯合空冷(leng)(leng)器(qi)。

④. 按(an)空(kong)冷(leng)器風量控制方式(shi)分(fen)類:百(bai)葉(xie)窗調(diao)節(jie)式(shi)全冷(leng)器;可變角調(diao)節(jie)式(shi)空(kong)冷(leng)器;電(dian)動機調(diao)速式(shi)空(kong)冷(leng)器。

圖(tu)7.14所(suo)示(shi)為(wei)不同類型空(kong)冷器示(shi)意圖(tu)。

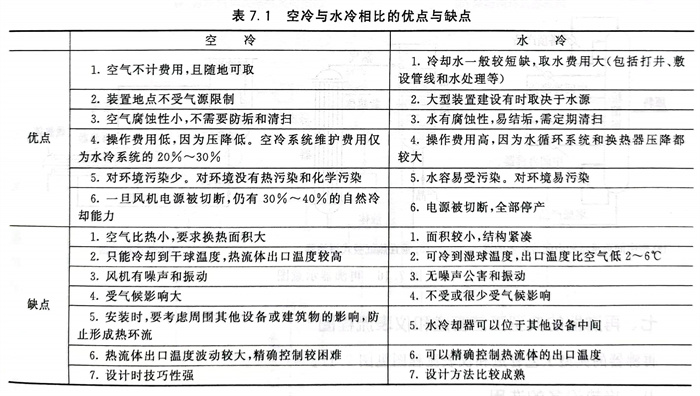

3. 空(kong)冷器的優(you)點(dian)與缺點(dian)