不(bu)銹鋼管渦流檢(jian)(jian)測(ce)(ce)是以交流電磁線(xian)圈在金(jin)屬構(gou)件表面(mian)感應產生渦流的無(wu)損檢(jian)(jian)測(ce)(ce)技術,它適(shi)用于(yu)導電材(cai)料(liao),可以檢(jian)(jian)測(ce)(ce)鐵磁性和(he)非鐵磁性金(jin)屬構(gou)件中的缺陷。由于(yu)渦流檢(jian)(jian)測(ce)(ce)在檢(jian)(jian)測(ce)(ce)時(shi)不(bu)要求線(xian)圈與構(gou)件緊密(mi)接觸(chu),也不(bu)需(xu)要耦合劑,容易實現自動(dong)化。但渦流檢(jian)(jian)測(ce)(ce)僅適(shi)用于(yu)導電材(cai)料(liao),只能檢(jian)(jian)測(ce)(ce)表面(mian)或(huo)近表面(mian)層的缺陷,不(bu)便使用于(yu)形(xing)狀復雜的構(gou)件。

將不(bu)銹鋼管放置在通以交流電的線圈中時,不銹鋼管表面會感生出周向電流。渦流磁場方向與外加電流的磁化方向相反,因此將抵消一部分外加電流,從而使線圈的阻抗、通過電流的大小、相位均發生變化。不銹鋼管的直徑、厚度、電導率和磁導率的變化以及有缺陷存在時,均會影響線圈的阻抗。若保持其他因素不變,僅將缺陷引起阻抗的變化信號取出,經儀器放大并予檢測,就能達到無損檢測的目的。

照(zhao)檢測(ce)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)的使用(yong)方式(shi),可分為絕對(dui)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)式(shi)、標準(zhun)比(bi)較(jiao)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)式(shi)和自比(bi)較(jiao)式(shi)等形(xing)式(shi)。只用(yong)一個檢測(ce)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)的稱(cheng)為絕對(dui)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)式(shi)。用(yong)兩個檢測(ce)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)接成(cheng)差(cha)動(dong)形(xing)式(shi),稱(cheng)為標準(zhun)比(bi)較(jiao)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)式(shi)。采用(yong)兩個線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)放(fang)于同(tong)一被檢構件的不(bu)同(tong)部位,作為比(bi)較(jiao)標準(zhun)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan),稱(cheng)為自比(bi)較(jiao)式(shi),是標準(zhun)比(bi)較(jiao)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)式(shi)的特例。基本電(dian)路由振蕩(dang)器、檢測(ce)線(xian)(xian)(xian)(xian)(xian)圈(quan)(quan)(quan)信號(hao)輸出電(dian)路、放(fang)大器、信號(hao)處(chu)理(li)器、顯示器和電(dian)源等部分組成(cheng)。

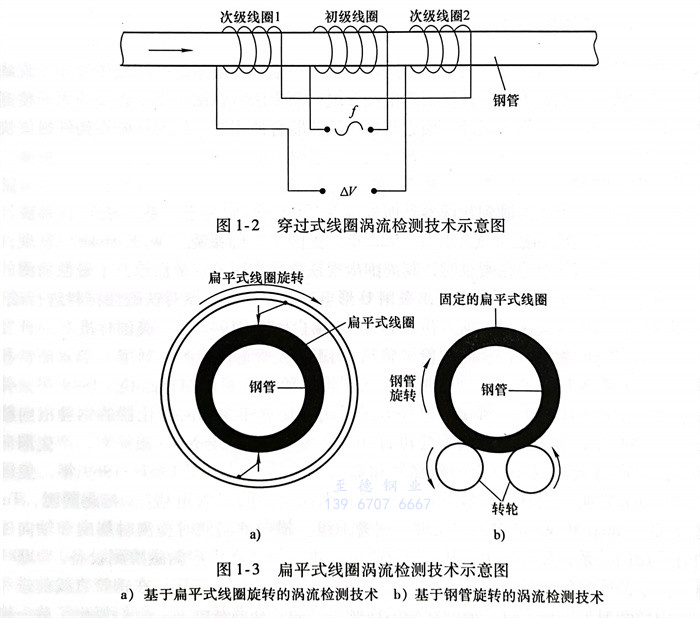

為使無縫鋼管和焊接鋼管在整個圓周面上都能進行無損檢測,可使用穿過式線圈渦流檢測技術,或者使用扁平式線圈檢測技術。當使用穿過式線圈對鋼管進行檢測時,如圖1-2所示,被檢不銹鋼管的最大外徑一般不超過180mm。當使用旋轉鋼管扁平式線圈檢測技術時,為實現對鋼管表面的全覆蓋檢測,需要形成線圈與不銹鋼管表面之間的相對移動掃描,如圖1-3所示。