不銹(xiu)鋼熱軋中厚板(ban)工藝技術(shu)裝(zhuang)備主要體現在爐(lu)卷軋機。

爐(lu)卷(juan)軋機技術始于20世紀(ji)(ji)30年代(dai)(dai),主要生(sheng)產厚度(du)3毫米以上(shang)的熱軋帶鋼(gang)。帶鋼(gang)進(jin)卷(juan)取(qu)爐(lu)的厚度(du)為15~17毫米,爐(lu)內溫度(du)950~1050℃,生(sheng)產能力20萬~30萬噸(dun)/年。20世紀(ji)(ji)50-60年代(dai)(dai)其發展(zhan)較快,至20世紀(ji)(ji)70年代(dai)(dai)全世界已(yi)建(jian)爐(lu)卷(juan)軋機約34套(tao),形成第(di)一次發展(zhan)高潮(chao)。但由于爐(lu)卷(juan)軋機存(cun)在諸(zhu)多不足,20世紀(ji)(ji)80年代(dai)(dai)初,仍在生(sheng)產的爐(lu)卷(juan)軋機已(yi)不超(chao)過20套(tao)。

20世紀80年代中后期爐卷軋機復興,以生產不(bu)銹鋼為主的爐卷軋機因采用多項熱連軋機的控制技術得到長足發展,已成為不銹鋼領域的主力熱軋機。采用爐卷軋機軋制不銹鋼的主要原因為:(1)爐卷軋機前后設保溫卷取爐,適合不銹鋼等加工溫度范圍窄、難變形金屬的軋制;(2)專業化不銹帶鋼廠規模在25萬~50萬噸/年,用爐卷軋機生產能力適中,投資低,效益好;(3)現代化的爐卷軋機由于采用了厚度自動控制、板形控制、多次高壓水除鱗、快速換輥裝置等,從而保證了產品的尺寸精度、表面質量及板形等;(4)爐卷軋機在特種材料的軋制方面優勢明顯,可實現卷板品種優化。

爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)可(ke)兼作軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)中(zhong)厚(hou)(hou)板(ban)(ban)。20世紀80-90年(nian)(nian)(nian)代新建(jian)的(de)(de)26套(tao)(tao)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)碳鋼(gang)(gang)不銹鋼(gang)(gang),其中(zhong)約15套(tao)(tao)兼作軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)中(zhong)厚(hou)(hou)板(ban)(ban),并配(pei)(pei)備(bei)了(le)中(zhong)厚(hou)(hou)板(ban)(ban)精(jing)軋(ya)(ya)(ya)(ya)(ya)(ya)線(xian)。在10套(tao)(tao)不銹鋼(gang)(gang)專用(yong)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)中(zhong),有5套(tao)(tao)兼作軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)中(zhong)厚(hou)(hou)板(ban)(ban),其中(zhong)輥身長度最大的(de)(de)是瑞典(dian)阿維斯(si)塔(Avesta)廠的(de)(de)2800毫米粗軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。2003年(nian)(nian)(nian)5月我國(guo)(guo)南(nan)京鋼(gang)(gang)鐵公(gong)(gong)司與奧鋼(gang)(gang)聯簽訂合同(tong)(tong),引(yin)進了(le)用(yong)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)工藝生(sheng)(sheng)(sheng)產(chan)(chan)的(de)(de)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji),并于2005年(nian)(nian)(nian)9月28日成功軋(ya)(ya)(ya)(ya)(ya)(ya)出第(di)一塊鋼(gang)(gang)板(ban)(ban)。同(tong)(tong)期,安(an)陽、韶關鋼(gang)(gang)鐵公(gong)(gong)司從達(da)涅(nie)利(li)公(gong)(gong)司引(yin)進用(yong)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)工藝生(sheng)(sheng)(sheng)產(chan)(chan)的(de)(de)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji),其中(zhong)安(an)鋼(gang)(gang)建(jian)設(she)(she)了(le)卷(juan)(juan)(juan)取(qu)(qu)爐(lu)(lu),但預(yu)留了(le)卷(juan)(juan)(juan)取(qu)(qu)機(ji)(ji),韶鋼(gang)(gang)對卷(juan)(juan)(juan)取(qu)(qu)爐(lu)(lu)和卷(juan)(juan)(juan)取(qu)(qu)機(ji)(ji)均(jun)做了(le)預(yu)留。在我國(guo)(guo)投(tou)產(chan)(chan)的(de)(de)3套(tao)(tao)中(zhong)厚(hou)(hou)板(ban)(ban)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)中(zhong),南(nan)鋼(gang)(gang)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)配(pei)(pei)備(bei)了(le)完整的(de)(de)板(ban)(ban)、卷(juan)(juan)(juan)生(sheng)(sheng)(sheng)產(chan)(chan)設(she)(she)備(bei),軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)力達(da)80兆(zhao)牛(niu),可(ke)較好(hao)地實現控制(zhi)(zhi)(zhi)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)和控制(zhi)(zhi)(zhi)冷卻工藝,在管線(xian)鋼(gang)(gang)生(sheng)(sheng)(sheng)產(chan)(chan)方面(mian)取(qu)(qu)得(de)了(le)較好(hao)的(de)(de)業績(ji)。我國(guo)(guo)已建(jian)成投(tou)產(chan)(chan)的(de)(de)板(ban)(ban)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)主要是在中(zhong)等規模的(de)(de)鋼(gang)(gang)廠,其利(li)用(yong)爐(lu)(lu)卷(juan)(juan)(juan)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)軋(ya)(ya)(ya)(ya)(ya)(ya)線(xian)設(she)(she)備(bei)少(shao)、投(tou)資省、產(chan)(chan)品市場適應面(mian)廣(guang)的(de)(de)特點,生(sheng)(sheng)(sheng)產(chan)(chan)中(zhong)厚(hou)(hou)板(ban)(ban)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)不宜(yi)軋(ya)(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)(zhi)的(de)(de)薄(bo)、窄規格中(zhong)板(ban)(ban),同(tong)(tong)時生(sheng)(sheng)(sheng)產(chan)(chan)熱連(lian)軋(ya)(ya)(ya)(ya)(ya)(ya)機(ji)(ji)不能生(sheng)(sheng)(sheng)產(chan)(chan)的(de)(de)寬規格熱軋(ya)(ya)(ya)(ya)(ya)(ya)卷(juan)(juan)(juan)。

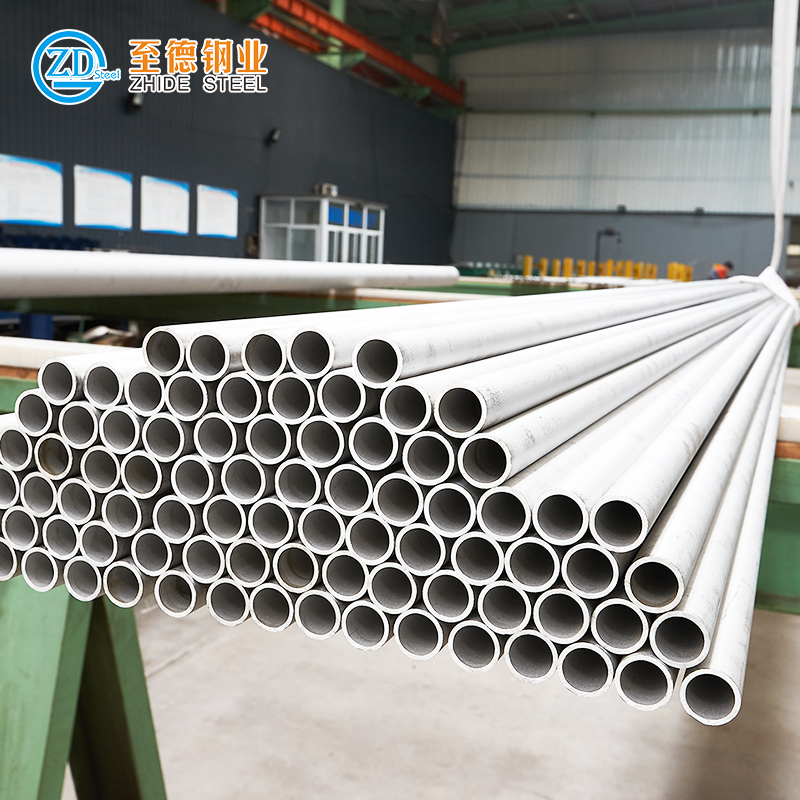

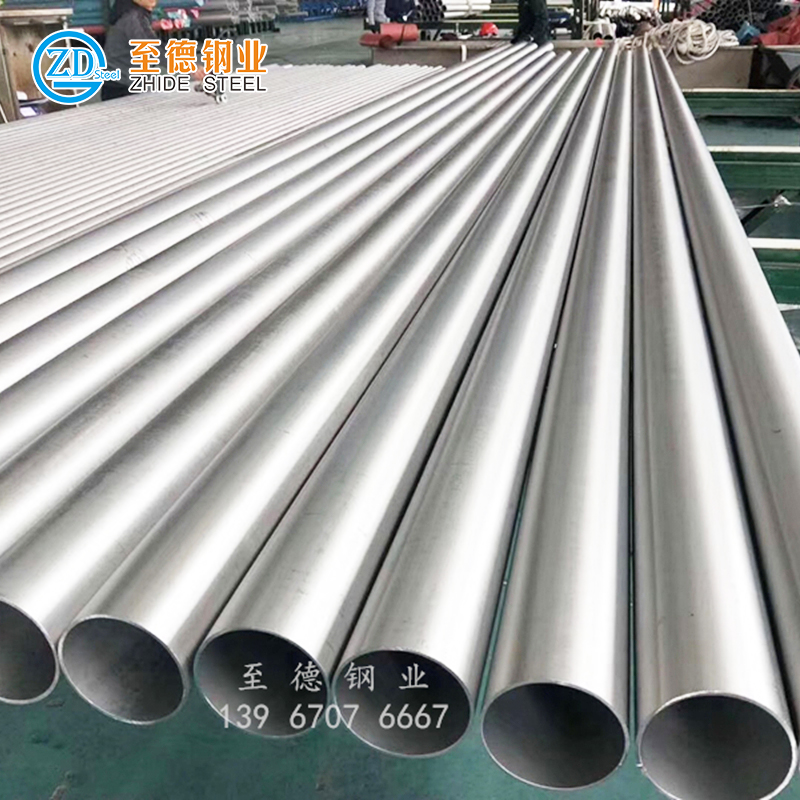

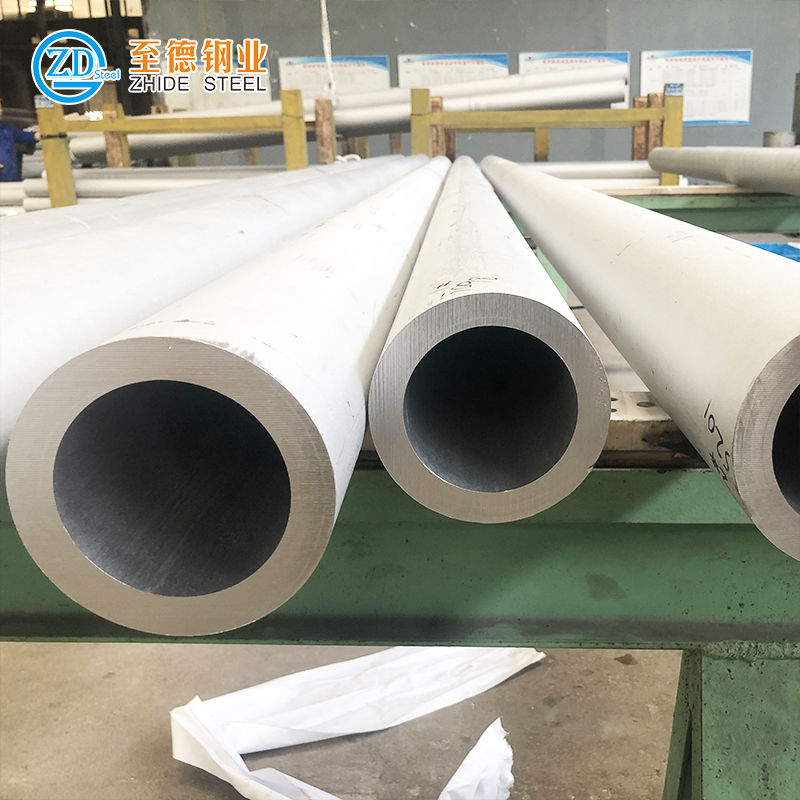

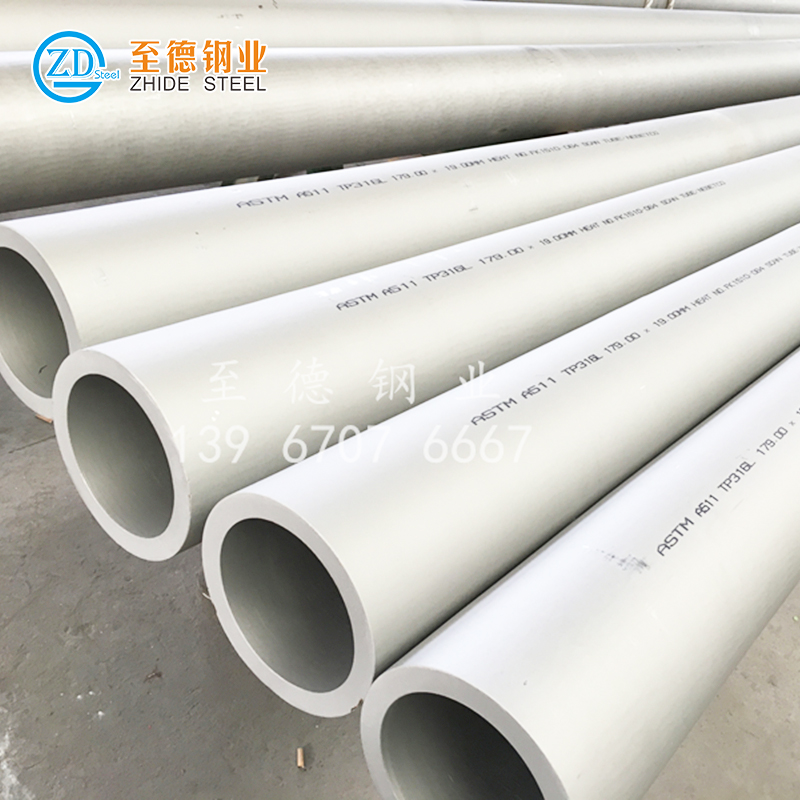

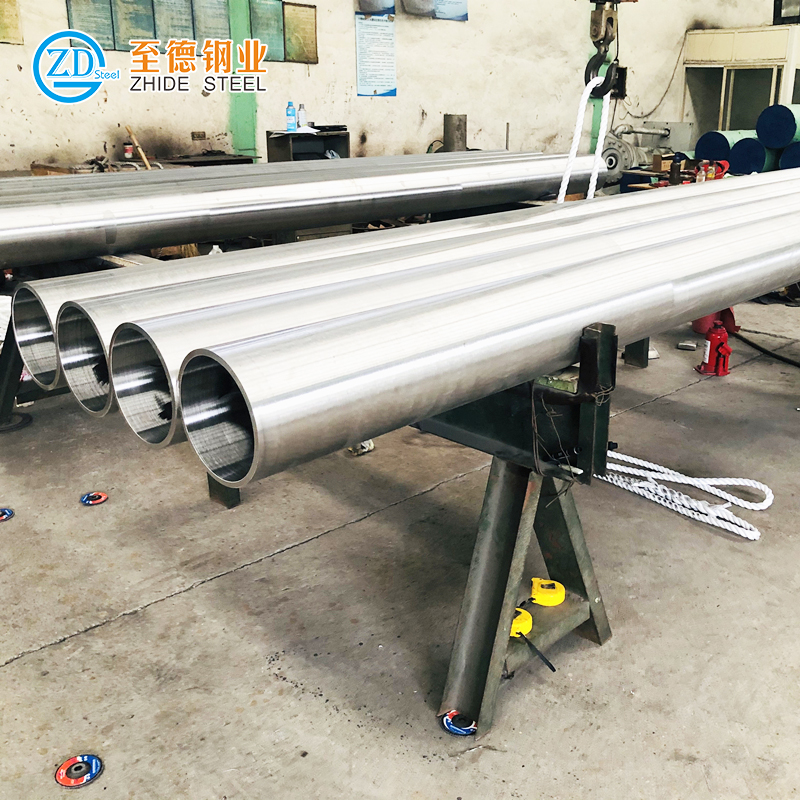

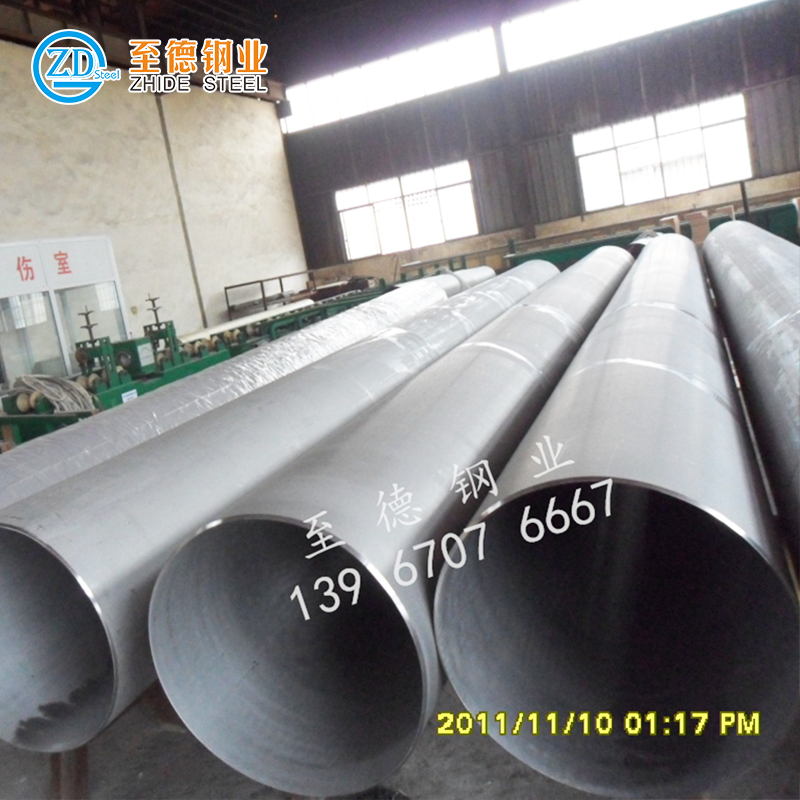

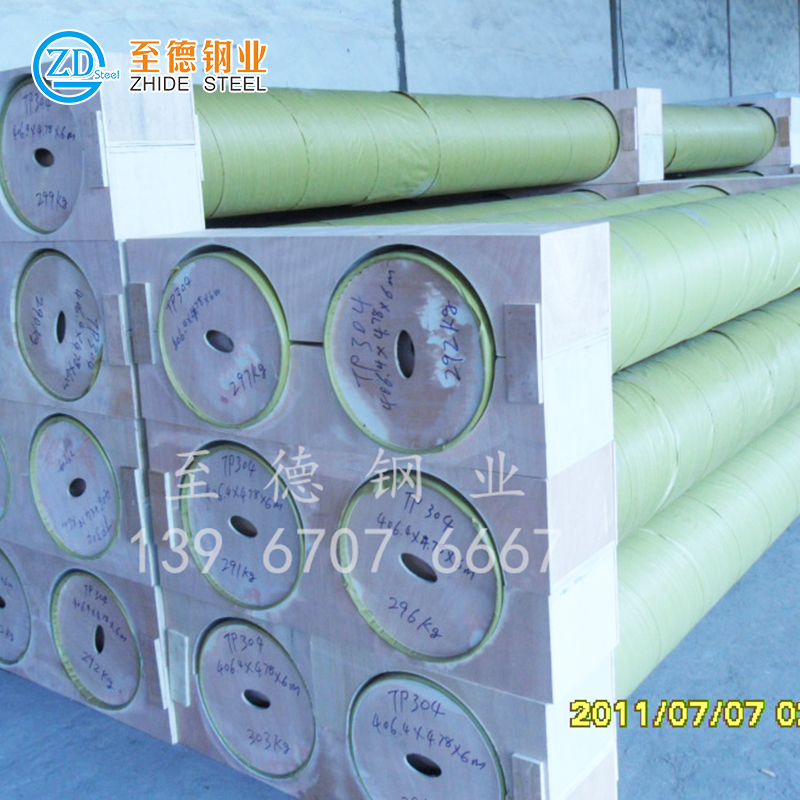

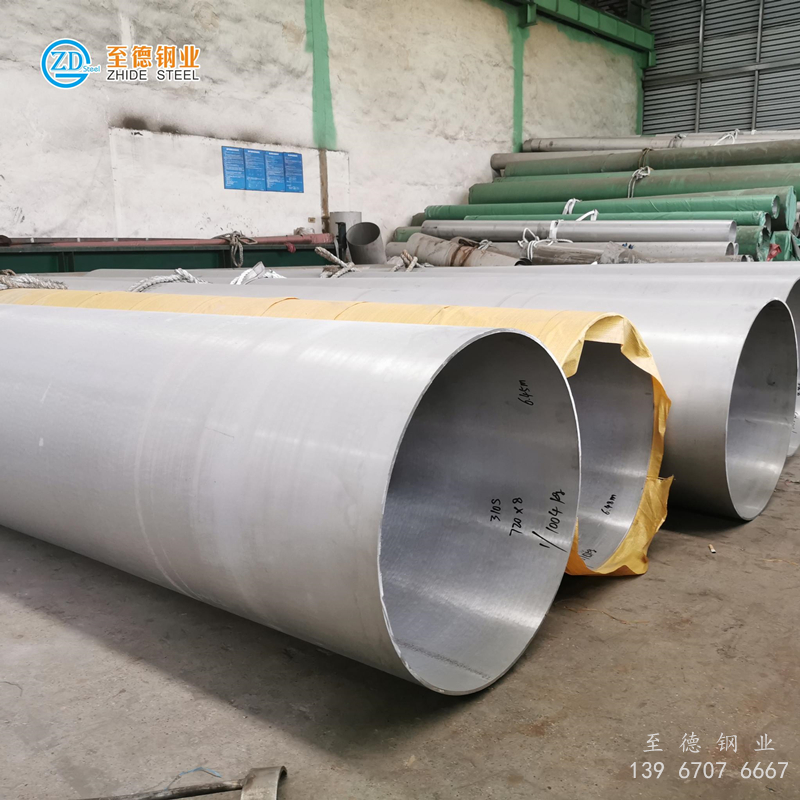

至德鋼(gang)(gang)業,我們根據(ju)您的實際需(xu)求,給出參(can)考建議,為您提供高性價比的不銹鋼(gang)(gang)管道及配件(jian)。