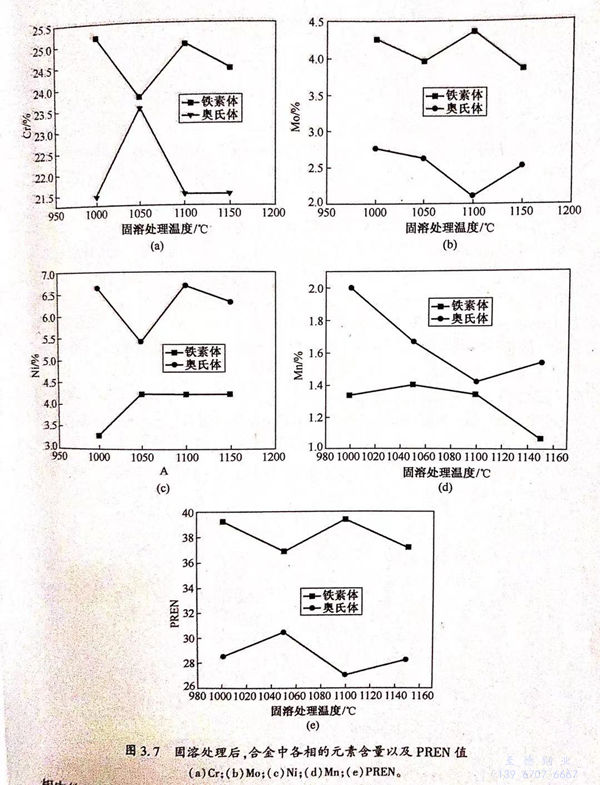

圖3.7(a)~(d)為(wei)(wei)(wei)(wei)(wei)鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)和(he)(he)奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo、Ni元(yuan)(yuan)素(su)(su)(su)(su)含(han)(han)(han)量(liang)(liang)與固溶(rong)(rong)溫(wen)(wen)(wen)度的(de)(de)(de)(de)關系(xi)圖。圖3.7(a)~(d)證實了鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr和(he)(he)Mo含(han)(han)(han)量(liang)(liang)更高,而奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Ni和(he)(he)Mn含(han)(han)(han)量(liang)(liang)更高。從圖中(zhong)(zhong)(zhong)(zhong)可看出,鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr含(han)(han)(han)量(liang)(liang)為(wei)(wei)(wei)(wei)(wei)23.77%~25.16%,比(bi)奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)Cr含(han)(han)(han)量(liang)(liang)高2%左右;鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)Mo含(han)(han)(han)量(liang)(liang)為(wei)(wei)(wei)(wei)(wei)3.86%~4.37%,比(bi)奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Mo含(han)(han)(han)量(liang)(liang)高1.7%左右;奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Ni含(han)(han)(han)量(liang)(liang)為(wei)(wei)(wei)(wei)(wei)5.42%、6.7%,比(bi)鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Ni含(han)(han)(han)量(liang)(liang)高2%;當(dang)固溶(rong)(rong)處(chu)理(li)溫(wen)(wen)(wen)度為(wei)(wei)(wei)(wei)(wei)1050℃時(shi),鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo和(he)(he)Ni含(han)(han)(han)量(liang)(liang)分(fen)別(bie)為(wei)(wei)(wei)(wei)(wei)23.77%、3.97%、4.24%,奧(ao)(ao)氏體(ti)(ti)(ti)(ti)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo和(he)(he)Ni含(han)(han)(han)量(liang)(liang)分(fen)別(bie)為(wei)(wei)(wei)(wei)(wei)23.53%、2.63%、5.42%.可見在1050℃溫(wen)(wen)(wen)度下進行固溶(rong)(rong)時(shi),兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo、Ni含(han)(han)(han)量(liang)(liang)差(cha)異最小(xiao),此(ci)時(shi)鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)含(han)(han)(han)量(liang)(liang)為(wei)(wei)(wei)(wei)(wei)51.9%,奧(ao)(ao)氏體(ti)(ti)(ti)(ti)含(han)(han)(han)量(liang)(liang)為(wei)(wei)(wei)(wei)(wei)48.1%.當(dang)固溶(rong)(rong)溫(wen)(wen)(wen)度改變時(shi),鐵(tie)(tie)素(su)(su)(su)(su)體(ti)(ti)(ti)(ti)/奧(ao)(ao)氏體(ti)(ti)(ti)(ti)兩(liang)(liang)(liang)相(xiang)(xiang)比(bi)例相(xiang)(xiang)差(cha)變大,且兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo、Ni含(han)(han)(han)量(liang)(liang)差(cha)異也(ye)變大。當(dang)固溶(rong)(rong)溫(wen)(wen)(wen)度為(wei)(wei)(wei)(wei)(wei)1000℃,兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)Cr為(wei)(wei)(wei)(wei)(wei)3.69%、Mo為(wei)(wei)(wei)(wei)(wei)1.51%、Ni為(wei)(wei)(wei)(wei)(wei)3.37%;當(dang)固溶(rong)(rong)溫(wen)(wen)(wen)度為(wei)(wei)(wei)(wei)(wei)1150℃時(shi),兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)Cr為(wei)(wei)(wei)(wei)(wei)2.29%、Mo為(wei)(wei)(wei)(wei)(wei)1.34%、Ni為(wei)(wei)(wei)(wei)(wei)2.09%,可見1000℃固溶(rong)(rong)試(shi)樣(yang)的(de)(de)(de)(de)兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)的(de)(de)(de)(de)Cr、Mo、Ni元(yuan)(yuan)素(su)(su)(su)(su)含(han)(han)(han)量(liang)(liang)差(cha)大于(yu)1150℃固溶(rong)(rong)試(shi)樣(yang)的(de)(de)(de)(de)兩(liang)(liang)(liang)相(xiang)(xiang)中(zhong)(zhong)(zhong)(zhong)Cr、Mo、Ni元(yuan)(yuan)素(su)(su)(su)(su)含(han)(han)(han)量(liang)(liang)差(cha)。

由(you)公(gong)式(shi)“PREN.=[Cr]+3.3[Mo]”計算(suan)鐵素體的(de)PREN值(zhi),由(you)公(gong)式(shi)“PREN,=[Cr]+3.3[Mo]+16[N]-[Mn]”計算(suan)奧氏體的(de)PREN值(zhi),可得PREN值(zhi)與固(gu)溶溫(wen)度(du)的(de)關系圖(tu),如圖(tu)3.7(e)所(suo)示。從(cong)圖(tu)3.7(e)可看出,在不同固(gu)溶狀態下,兩(liang)相的(de)PREN值(zhi)有(you)所(suo)不同,但(dan)PRENa>PRENy.當固(gu)溶溫(wen)度(du)為(wei)1050℃時,PREN.最小(xiao)、PREN,最大,分別為(wei)36.9和30.6,兩(liang)者相差(cha)最小(xiao)。

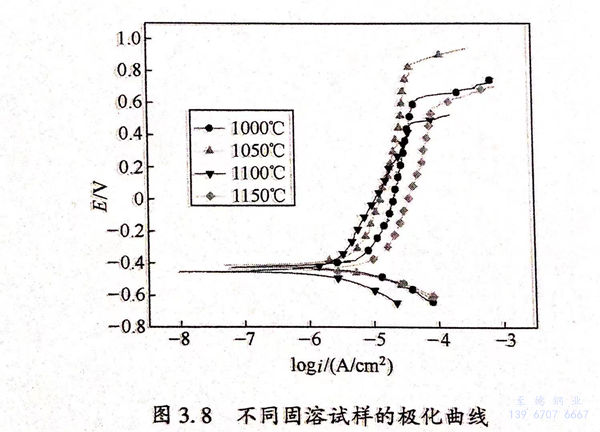

圖(tu)3.8為(wei)(wei)不同(tong)固溶試樣的極(ji)化曲線。可(ke)見(jian),在自(zi)(zi)腐(fu)蝕電(dian)位(wei)下,材料開(kai)始發生(sheng)鈍(dun)化;當(dang)極(ji)化電(dian)位(wei)升高到(dao)一定值時,不同(tong)固溶的材料都發生(sheng)點蝕,電(dian)流密度急劇增大。根據(ju)GB 4334.9-1984中電(dian)流密度為(wei)(wei)0.1mA/c㎡所對(dui)應的電(dian)位(wei)為(wei)(wei)點蝕電(dian)位(wei)和(he)Tafel擬合,分別得到(dao)點蝕電(dian)位(wei)、自(zi)(zi)腐(fu)蝕電(dian)流密度與固溶溫度的關系圖(tu),如圖(tu)3.11(a)所示。

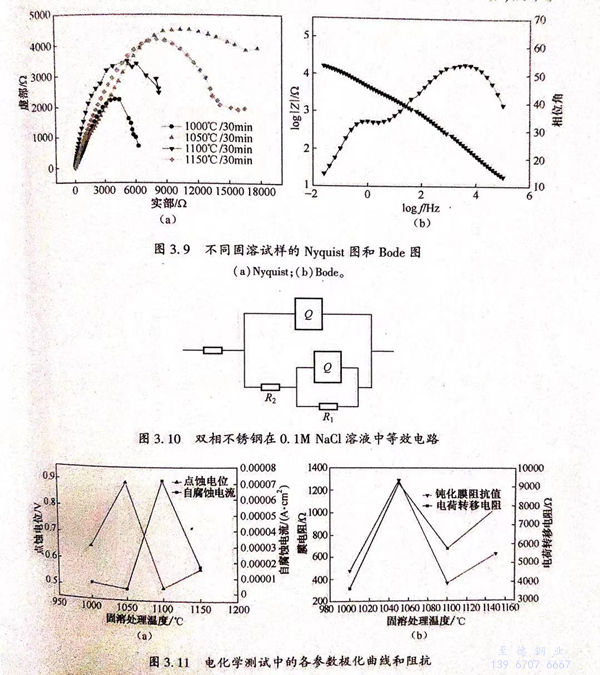

圖(tu)(tu)(tu)(tu)3.9(a)、(b)分(fen)別(bie)為(wei)不(bu)同(tong)固溶(rong)試樣(yang)的(de)Nyquist 圖(tu)(tu)(tu)(tu)和Bode圖(tu)(tu)(tu)(tu)。從(cong)圖(tu)(tu)(tu)(tu)3.9(a)可見(jian),試樣(yang)在低頻和高頻區分(fen)別(bie)存(cun)在一個容抗弧。從(cong)圖(tu)(tu)(tu)(tu)3.9(b)可見(jian),試樣(yang)在低頻和高頻處分(fen)別(bie)存(cun)在一個時間常數。根據曹楚南的(de)《電(dian)化學阻(zu)(zu)抗譜導(dao)論》可知(zhi)。雙相不(bu)銹鋼在NaCl溶(rong)液中(zhong)的(de)阻(zu)(zu)抗譜中(zhong)存(cun)在兩個時間常數,常以圖(tu)(tu)(tu)(tu)3.10所示的(de)等效電(dian)路(R1為(wei)電(dian)荷(he)轉移電(dian)阻(zu)(zu),R2為(wei)鈍化膜電(dian)阻(zu)(zu))進行阻(zu)(zu)抗擬合。經阻(zu)(zu)抗擬合,得到鈍化膜電(dian)阻(zu)(zu)、電(dian)荷(he)轉移電(dian)阻(zu)(zu)與(yu)固溶(rong)處理溫度(du)的(de)關系(xi)圖(tu)(tu)(tu)(tu),如圖(tu)(tu)(tu)(tu)3.11(b)所示。

從圖3.11(a)可見,1050℃固溶試樣的點蝕電位最高,約為0.89V,且1050℃固溶試樣的自腐蝕電流密度最低,約為2.34×10-6A/c㎡,說明該狀態下試樣的耐點蝕性能最好。由圖3.11(b)可知,1050℃固溶試樣的鈍化膜電阻值最高,約為1300Ω,且其電荷轉移電阻值也最高,約為9500Ω,說明該狀態下試樣的鈍化膜較穩定,耐點蝕性能較好。

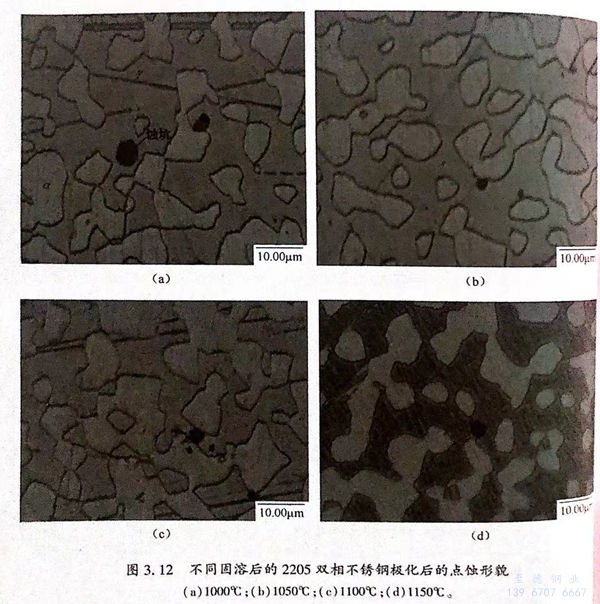

圖3.12為不同固溶的2205雙(shuang)相(xiang)不銹鋼極化后的點蝕形貌圖,圖中黑色為蝕坑,深色為鐵素體,淡色為奧氏體。從圖3.12可見,四種固溶試樣的點蝕都發生于鐵素體與奧氏體相界面處,且易向鐵素體相中長大。當固溶溫度為1050℃時,試樣的點蝕尺寸最小,點蝕敏感性最低。

通過計算得(de)到不(bu)(bu)同(tong)相(xiang)比例(li)下(xia)的(de)(de)鐵素體(ti)PREN值(zhi)(zhi)和(he)奧氏體(ti)PREN值(zhi)(zhi),可(ke)(ke)見不(bu)(bu)同(tong)相(xiang)比例(li)下(xia)的(de)(de)PREN.都(dou)大于PREN,.雙相(xiang)不(bu)(bu)銹(xiu)(xiu)鋼(gang)的(de)(de)耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)可(ke)(ke)通過點(dian)蝕(shi)(shi)(shi)電(dian)位衡量。點(dian)蝕(shi)(shi)(shi)電(dian)位越(yue)高,耐(nai)(nai)(nai)點(dian)獨性(xing)(xing)能(neng)越(yue)好。前人(ren)認(ren)為(wei)雙相(xiang)不(bu)(bu)銹(xiu)(xiu)鋼(gang)的(de)(de)耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)由B能(neng)N值(zhi)(zhi)較區的(de)(de)相(xiang)決(jue)定(ding),且PEN值(zhi)(zhi)越(yue)高,耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)越(yue)好,從(cong)圖(tu)(tu)3.71e)可(ke)(ke)矩,不(bu)(bu)同(tong)海溶(rong)試(shi)(shi)樣的(de)(de)PREN.都(dou)大于PREN,,當固溶(rong)溫度為(wei)1050℃時,PHEN,最(zui)大,材料的(de)(de)耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)應最(zui)好。從(cong)圖(tu)(tu)3.11(a)、(b)可(ke)(ke)知,1050℃固溶(rong)試(shi)(shi)樣的(de)(de)點(dian)蝕(shi)(shi)(shi)電(dian)位最(zui)高,鈍化膜阻(zu)抗(kang)值(zhi)(zhi)最(zui)大,電(dian)荷轉移(yi)電(dian)阻(zu)值(zhi)(zhi)最(zui)商;且從(cong)圖(tu)(tu)3.12(b)可(ke)(ke)見,1050℃固溶(rong)試(shi)(shi)樣的(de)(de)點(dian)蝕(shi)(shi)(shi)坑尺寸(cun)最(zui)小,表現出最(zui)好的(de)(de)耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)。綜(zong)上(shang)可(ke)(ke)知,雙相(xiang)不(bu)(bu)銹(xiu)(xiu)鋼(gang)的(de)(de)耐(nai)(nai)(nai)點(dian)蝕(shi)(shi)(shi)性(xing)(xing)能(neng)由 PREN 值(zhi)(zhi)較小相(xiang)決(jue)定(ding)的(de)(de)理論是有實驗依(yi)據的(de)(de)。

從圖3.12(a)~(d)可(ke)見,在不同固溶(rong)狀態(tai)(tai)下,鐵素體(ti)相都(dou)更易(yi)發(fa)生點(dian)(dian)蝕;而(er)從圖3.7(e)可(ke)見,在不同固溶(rong)狀態(tai)(tai)下,PREN.都(dou)大于PREN,,鐵素體(ti)的耐點(dian)(dian)蝕性能應優于奧(ao)氏體(ti)相,可(ke)見兩者(zhe)存在矛盾。

隨固(gu)溶(rong)溫度變(bian)(bian)化(hua),雙(shuang)相(xiang)不(bu)(bu)銹鋼中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)鐵素(su)(su)(su)(su)體(ti)和奧(ao)氏(shi)體(ti)相(xiang)的(de)(de)(de)(de)(de)比例改變(bian)(bian),且兩(liang)相(xiang)形態也(ye)發(fa)生(sheng)變(bian)(bian)化(hua)。Cr是鐵素(su)(su)(su)(su)體(ti)形成(cheng)元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su),可(ke)提(ti)高材(cai)料(liao)的(de)(de)(de)(de)(de)耐(nai)(nai)蝕(shi)(shi)性(xing)能;Mo是鐵素(su)(su)(su)(su)體(ti)形成(cheng)元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su),可(ke)提(ti)高點蝕(shi)(shi)電(dian)位(wei),降低腐(fu)蝕(shi)(shi)速率;Ni是奧(ao)氏(shi)體(ti)形成(cheng)元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su),可(ke)維持兩(liang)相(xiang)平衡,提(ti)高耐(nai)(nai)蝕(shi)(shi)性(xing)能。并且材(cai)料(liao)中(zhong)(zhong)(zhong)存(cun)(cun)在(zai)(zai)一定量的(de)(de)(de)(de)(de)N,其為(wei)(wei)奧(ao)氏(shi)體(ti)形成(cheng)元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su),提(ti)高局部(bu)腐(fu)蝕(shi)(shi)抗力(li)。從圖3.7(a)~(c)可(ke)見,隨固(gu)溶(rong)溫度變(bian)(bian)化(hua),兩(liang)相(xiang)中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)Cr、Mo、Ni元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)含量發(fa)生(sheng)變(bian)(bian)化(hua)。由(you)于(yu)Cr、Mo、Ni元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)之間(jian)(jian)的(de)(de)(de)(de)(de)腐(fu)蝕(shi)(shi)電(dian)位(wei)存(cun)(cun)在(zai)(zai)差異,勢必(bi)造成(cheng)兩(liang)相(xiang)之間(jian)(jian)存(cun)(cun)在(zai)(zai)電(dian)化(hua)學差異,使腐(fu)蝕(shi)(shi)更易(yi)發(fa)生(sheng)。從圖3.7(e)可(ke)知,不(bu)(bu)同(tong)(tong)固(gu)溶(rong)狀(zhuang)態下材(cai)料(liao)的(de)(de)(de)(de)(de)PREN,大(da)(da)小(xiao)關(guan)系為(wei)(wei)1050℃>1000℃>1150℃>1100℃,因(yin)此(ci)(ci)根據(ju)前人(ren)的(de)(de)(de)(de)(de)研(yan)究,不(bu)(bu)同(tong)(tong)固(gu)溶(rong)態材(cai)料(liao)的(de)(de)(de)(de)(de)耐(nai)(nai)點蝕(shi)(shi)性(xing)能優(you)(you)劣關(guan)系應為(wei)(wei):1050℃優(you)(you)于(yu)1000℃優(you)(you)于(yu)1150℃.當固(gu)溶(rong)溫度為(wei)(wei)1050℃時,PREN,值較大(da)(da),兩(liang)相(xiang)中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)Cr、Mo、Ni元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)含量差異最小(xiao),材(cai)料(liao)的(de)(de)(de)(de)(de)點蝕(shi)(shi)坑較小(xiao),材(cai)料(liao)的(de)(de)(de)(de)(de)耐(nai)(nai)點蝕(shi)(shi)性(xing)能最優(you)(you)。1000℃固(gu)溶(rong)試樣(yang)(yang)(yang)的(de)(de)(de)(de)(de)點蝕(shi)(shi)坑尺寸大(da)(da)于(yu)1150℃固(gu)溶(rong)試樣(yang)(yang)(yang)的(de)(de)(de)(de)(de)點蝕(shi)(shi)坑尺寸,因(yin)此(ci)(ci),前者的(de)(de)(de)(de)(de)耐(nai)(nai)點蝕(shi)(shi)性(xing)能劣于(yu)后者的(de)(de)(de)(de)(de)耐(nai)(nai)點蝕(shi)(shi)性(xing)能。由(you)此(ci)(ci)可(ke)見,雙(shuang)相(xiang)不(bu)(bu)銹鋼中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)相(xiang)腐(fu)蝕(shi)(shi)不(bu)(bu)能僅僅由(you)PREN值來解釋。由(you)圖3.7(a)~(c)可(ke)知,1000℃固(gu)溶(rong)試樣(yang)(yang)(yang)的(de)(de)(de)(de)(de)兩(liang)相(xiang)中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)Cr、Mo、Ni元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)含量差大(da)(da)于(yu)1150℃固(gu)溶(rong)試樣(yang)(yang)(yang)的(de)(de)(de)(de)(de)兩(liang)相(xiang)中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)Gr、Mo、Ni元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)含量差,因(yin)此(ci)(ci),雙(shuang)相(xiang)不(bu)(bu)銹鋼中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)相(xiang)腐(fu)蝕(shi)(shi)還與兩(liang)相(xiang)中(zhong)(zhong)(zhong)的(de)(de)(de)(de)(de)元(yuan)(yuan)(yuan)(yuan)素(su)(su)(su)(su)分布有(you)關(guan),并且還需考慮(lv)到材(cai)料(liao)中(zhong)(zhong)(zhong)點蝕(shi)(shi)敏感性(xing)較強的(de)(de)(de)(de)(de)區域,如晶界和相(xiang)界。

點蝕(shi)是一種局部腐蝕現象,是由氯離子破壞鈍化膜而導致的。點蝕產生后,蝕坑處的基體被暴露在溶液中,導致材料進一步發生腐蝕,蝕坑長大。蝕坑前長大速率由材料的均勻溶解速率決定,溶解越快,蝕坑長大速度越大。因此,雙相不銹鋼的耐點蝕性能由兩部分構成:控制點蝕萌生和控制蝕坑長大的能力。本書中的點蝕電位意味著點蝕已長大。影響點蝕萌生的因素不僅包括PREN 值,還包括兩相中的元素分布和兩相的比例。從本書的分析可見,點蝕的長大與元素分布有關,兩相中的元素分布越均勻,蝕坑的長大速度越慢。因此在1050℃固溶狀態下,兩相中的元素分布最均勻,PREN,最高,合金的點蝕電位最高,材料的耐點蝕性能最好。而1000℃固溶試樣兩相中的元素分布不均勻,導致點蝕電位較低,點蝕坑尺寸較大,降低材料的耐點蝕性能。

影(ying)響(xiang)雙相(xiang)(xiang)不(bu)銹鋼相(xiang)(xiang)腐蝕的因(yin)(yin)素不(bu)僅包(bao)括PREN值,還(huan)包(bao)括各(ge)相(xiang)(xiang)中(zhong)的元素分布(bu)和兩相(xiang)(xiang)比例(li),并且三者(zhe)互相(xiang)(xiang)影(ying)響(xiang)、關系復雜。因(yin)(yin)此(ci),不(bu)能僅憑PREN值的大小來判斷耐點(dian)蝕能力,應該綜合考(kao)慮各(ge)因(yin)(yin)素的影(ying)響(xiang)。