甲(jia)型(xing)和(he)乙(yi)型(xing)平焊(han)(han)法(fa)蘭(lan)的(de)法(fa)蘭(lan)環(huan)與圓筒(tong)或(huo)短(duan)節的(de)連接(jie)焊(han)(han)縫(feng)應全(quan)焊(han)(han)透。長頸對(dui)(dui)焊(han)(han)法(fa)蘭(lan)與筒(tong)的(de)對(dui)(dui)接(jie)焊(han)(han)縫(feng)應為全(quan)焊(han)(han)透焊(han)(han)縫(feng)。焊(han)(han)縫(feng)應充滿、完整(zheng),不得有凹(ao)坑(keng)等危及(ji)強(qiang)度的(de)缺陷。

法蘭的(de)焊接應依(yi)據可(ke)靠的(de)焊接工藝評定(ding),以確保焊接質量。

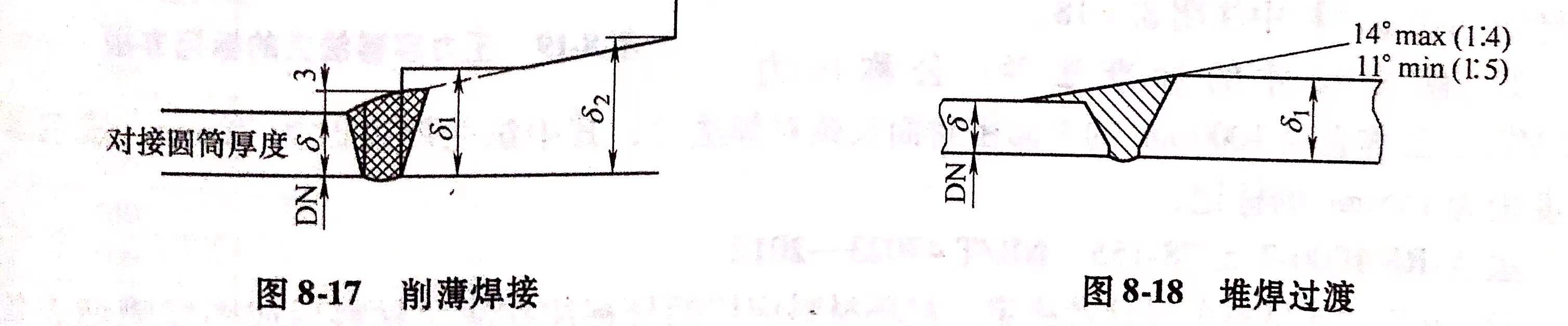

乙型(xing)法(fa)蘭的短(duan)(duan)節厚(hou)(hou)度(du)或(huo)(huo)長頸法(fa)蘭的直(zhi)邊厚(hou)(hou)度(du)與(yu)其相連接(jie)的圓筒(tong)(tong)(tong)(tong)厚(hou)(hou)度(du)不等時:①. 若圓筒(tong)(tong)(tong)(tong)厚(hou)(hou)度(du)不大于10mm,且與(yu)短(duan)(duan)節或(huo)(huo)長頸直(zhi)邊厚(hou)(hou)度(du)差超(chao)過3mm; ②. 若圓筒(tong)(tong)(tong)(tong)厚(hou)(hou)度(du)大于10mm,且與(yu)短(duan)(duan)節或(huo)(huo)長頸直(zhi)邊厚(hou)(hou)度(du)差大于筒(tong)(tong)(tong)(tong)體厚(hou)(hou)度(du)的30%或(huo)(huo)超(chao)過5mm時,乙型(xing)平焊法(fa)蘭應按(an)斜率1:3、長頸對焊法(fa)蘭按(an)圖8-17虛線(xian)削薄,或(huo)(huo)者在對接(jie)焊縫的筒(tong)(tong)(tong)(tong)體端部(bu)按(an)圖8-18堆焊過渡。

與長頸法蘭相連接的圓筒厚度應不小于JB/T 4703-2000《長頸對焊法蘭》中規定的對接筒體最小厚度δ0,且筒節長度不小于。當對接圓筒厚度小于最小對接圓筒厚度δ0時,應按JB/T 4703中有關長頸對焊法蘭總高度H修正值要求(見表8-11),調整法蘭總高度H(其他尺寸不變),并連同法蘭厚度在標記中標明。