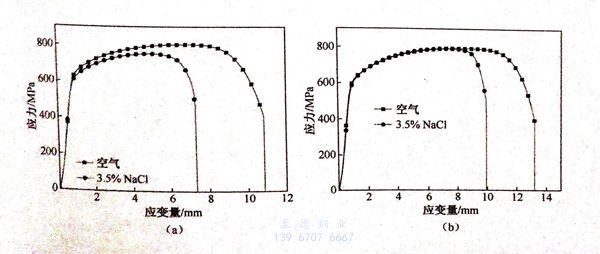

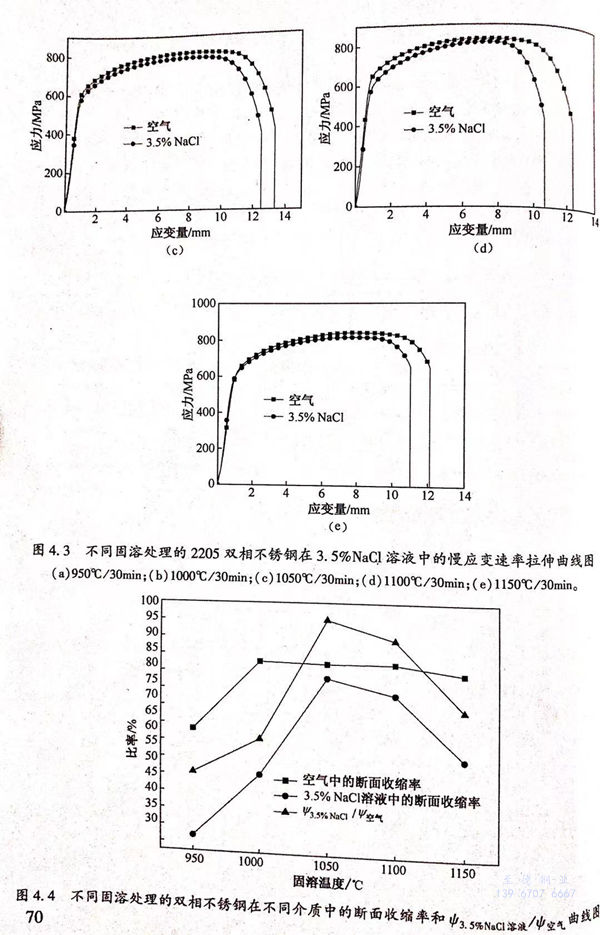

不同固溶處理的2205不銹鋼在3.5%NaCl溶液中的慢應變拉伸曲線如圖4.3所示。慢應變拉伸數據得到的各相性能指標值如圖4.4和表4.2所示。

材料的應力腐蝕敏感性的強弱可以用其比值來反映:該值越大,材料的應力腐蝕敏感性越低。從圖4.4可以看出,隨著固溶處理的溫度的升高,雙相不銹鋼在空氣中的斷面收縮率先升高后下降,雙相不(bu)銹鋼在溶液中斷面收縮率先升高后下降,以及兩者之比(ψ環境/ψ空氣)的值先升高后下降,說明隨著固溶處理的溫度從950℃升高至1150℃,雙相不銹鋼的應力腐蝕敏感性先變弱后變強。

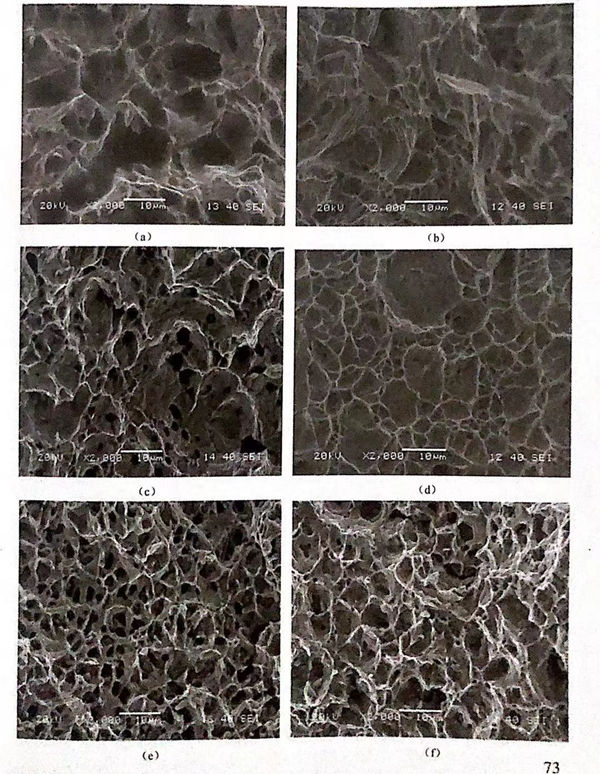

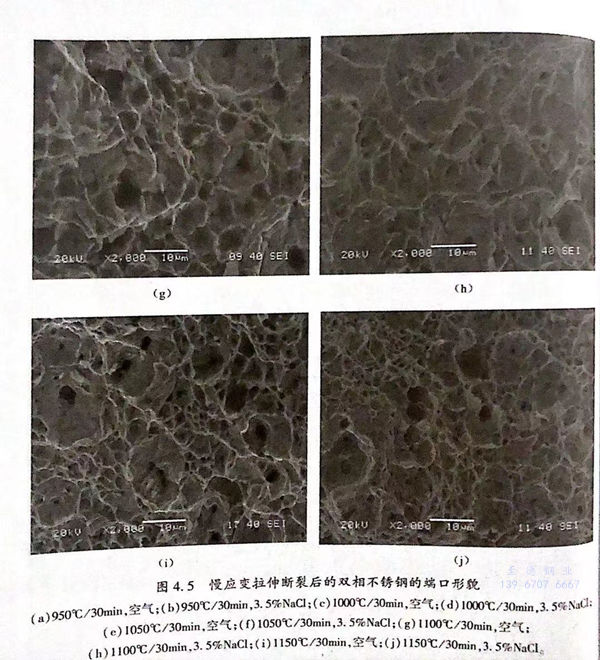

慢應變拉伸斷裂(lie)(lie)(lie)后(hou)的(de)雙(shuang)相(xiang)不(bu)銹(xiu)鋼(gang)(gang)(gang)的(de)斷口(kou)形貌如圖(tu)4.5所(suo)示。圖(tu)4.6為1050℃/30min 固(gu)溶(rong)處理的(de)雙(shuang)相(xiang)不(bu)銹(xiu)鋼(gang)(gang)(gang)在3.5%NaCl溶(rong)液(ye)中(zhong)(zhong)(zhong)慢應變拉伸后(hou)的(de)斷口(kou)剖面圖(tu)。從圖(tu)4.6中(zhong)(zhong)(zhong)可以看出,雙(shuang)相(xiang)不(bu)銹(xiu)鋼(gang)(gang)(gang)中(zhong)(zhong)(zhong)的(de)斷口(kou)形貌中(zhong)(zhong)(zhong)存在由裂(lie)(lie)(lie)紋(wen),裂(lie)(lie)(lie)紋(wen)的(de)源(yuan)頭在雙(shuang)相(xiang)不(bu)銹(xiu)鋼(gang)(gang)(gang)試(shi)樣(yang)表(biao)(biao)面,裂(lie)(lie)(lie)紋(wen)由雙(shuang)相(xiang)不(bu)銹(xiu)鋼(gang)(gang)(gang)表(biao)(biao)面相(xiang)試(shi)樣(yang)內部延伸,并終止于奧氏體,說明奧氏體對應力腐蝕的(de)裂(lie)(lie)(lie)紋(wen)的(de)擴展有(you)一定的(de)阻礙作用。

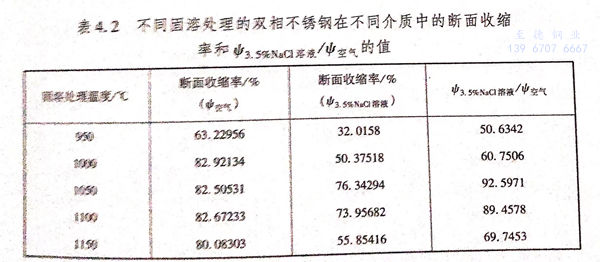

從表4.2中(zhong)(zhong)(zhong)(zhong)可以看出,當(dang)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)從950℃升高(gao)(gao)(gao)至(zhi)1000℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)的斷面(mian)收(shou)(shou)縮(suo)率(lv)從63.22956%升高(gao)(gao)(gao)至(zhi)82.92134%,升高(gao)(gao)(gao)幅值約為(wei)(wei)19%;當(dang)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)升高(gao)(gao)(gao)到(dao)1050℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)斷面(mian)收(shou)(shou)縮(suo)率(lv)為(wei)(wei)82.50531%;當(dang)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)為(wei)(wei)1100℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)斷面(mian)收(shou)(shou)縮(suo)率(lv)為(wei)(wei)82.67233%;進一步升高(gao)(gao)(gao)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)至(zhi)1150℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)斷面(mian)收(shou)(shou)縮(suo)率(lv)為(wei)(wei)80.08303%.可以看出,當(dang)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)從1000℃升高(gao)(gao)(gao)至(zhi)1100℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)的斷面(mian)收(shou)(shou)縮(suo)率(lv)幾乎沒有(you)變化,當(dang)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的溫度(du)升高(gao)(gao)(gao)至(zhi)1150℃時(shi),雙(shuang)(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)(gang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)斷面(mian)收(shou)(shou)縮(suo)率(lv)開(kai)始下(xia)降至(zhi)80.08303%,這與1150℃/30min固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的試樣(yang)中(zhong)(zhong)(zhong)(zhong)的鐵(tie)素(su)體和奧氏體的百(bai)分(fen)(fen)含量(liang)有(you)關(guan),此時(shi)的鐵(tie)素(su)體的百(bai)分(fen)(fen)含量(liang)為(wei)(wei)59%,而奧氏體的百(bai)分(fen)(fen)含量(liang)為(wei)(wei)41%,即(ji)1150℃/30min 固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的試樣(yang)中(zhong)(zhong)(zhong)(zhong)含有(you)過量(liang)的強度(du)高(gao)(gao)(gao)的鐵(tie)素(su)體,以及不(bu)足量(liang)的塑(su)性優的奧氏體,導致(zhi)該(gai)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)狀態(tai)下(xia)的試樣(yang)在空(kong)(kong)氣中(zhong)(zhong)(zhong)(zhong)的斷面(mian)收(shou)(shou)縮(suo)率(lv)有(you)所下(xia)降。對(dui)于950℃固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)的試樣(yang),其(qi)含有(you)6.1%的硬(ying)而脆的σ相(xiang),這必然(ran)導致(zhi)該(gai)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)狀態(tai)下(xia)的試樣(yang)的斷面(mian)收(shou)(shou)縮(suo)率(lv)明顯降低(di),僅為(wei)(wei)63.22956%。

從圖4.5(a)、(b)中(zhong)可(ke)(ke)以看出,950℃/30min固溶(rong)(rong)處理的(de)(de)雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)在(zai)(zai)空(kong)氣中(zhong)和溶(rong)(rong)液(ye)(ye)(ye)中(zhong)的(de)(de)斷(duan)口均呈(cheng)現準解理平面;950℃/30min 固溶(rong)(rong)處理的(de)(de)雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)在(zai)(zai)空(kong)氣中(zhong)的(de)(de)斷(duan)口局部有少量韌(ren)(ren)窩存(cun)在(zai)(zai),而在(zai)(zai)溶(rong)(rong)液(ye)(ye)(ye)中(zhong)的(de)(de)斷(duan)口幾(ji)乎是準解理平面,二者都(dou)(dou)屬于(yu)脆(cui)性(xing)斷(duan)裂,這(zhe)主要是由(you)于(yu)大(da)量脆(cui)性(xing)σ相(xiang)沿著晶界(jie)析出,降低了材料(liao)的(de)(de)耐(nai)應力腐蝕性(xing)能和力學性(xing)能。從圖4.5(e)、(f)中(zhong)可(ke)(ke)以看出,1050℃/30min固溶(rong)(rong)處理的(de)(de)雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)在(zai)(zai)空(kong)氣和溶(rong)(rong)液(ye)(ye)(ye)中(zhong)的(de)(de)斷(duan)口都(dou)(dou)存(cun)在(zai)(zai)大(da)量韌(ren)(ren)窩,雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)在(zai)(zai)溶(rong)(rong)液(ye)(ye)(ye)中(zhong)的(de)(de)韌(ren)(ren)性(xing)損失較小(xiao),而(950℃、1000℃、1100℃、1150℃)/30min 固溶(rong)(rong)處理的(de)(de)雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)在(zai)(zai)溶(rong)(rong)液(ye)(ye)(ye)中(zhong)都(dou)(dou)存(cun)在(zai)(zai)較大(da)的(de)(de)韌(ren)(ren)性(xing)損失,表明(ming)1050℃/30min 固溶(rong)(rong)處理的(de)(de)雙(shuang)相(xiang)不(bu)銹(xiu)(xiu)鋼(gang)具有較好(hao)的(de)(de)耐(nai)應力腐蝕性(xing)能。

從(cong)表4.2中(zhong)(zhong)也(ye)(ye)可以(yi)(yi)(yi)看出,950℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)在(zai)(zai)3.5%NaCl溶(rong)(rong)(rong)(rong)(rong)液(ye)(ye)中(zhong)(zhong)的(de)(de)(de)(de)斷(duan)面收縮率(lv)僅(jin)為(wei)32.0158%,其ψ3.5%NaCI溶(rong)(rong)(rong)(rong)(rong)液(ye)(ye)/空(kong)氣(qi)也(ye)(ye)僅(jin)為(wei)50.6342%,表現出很強(qiang)的(de)(de)(de)(de)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)敏(min)感(gan)性(xing)(xing),具有(you)差的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)。而1050℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)在(zai)(zai)3.5%NaCl 溶(rong)(rong)(rong)(rong)(rong)液(ye)(ye)中(zhong)(zhong)斷(duan)面收縮率(lv)達到(dao) 76.34294%,且其43.5%NaCI溶(rong)(rong)(rong)(rong)(rong)液(ye)(ye)/空(kong)氣(qi)也(ye)(ye)達到(dao)92.5971%,幾乎無應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)敏(min)感(gan)性(xing)(xing),表現出較(jiao)好的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)。1150℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)的(de)(de)(de)(de)43.5%NaCI溶(rong)(rong)(rong)(rong)(rong)液(ye)(ye)/4空(kong)氣(qi)值為(wei)69.7453%,與1050℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)相比較(jiao),有(you)明顯的(de)(de)(de)(de)下降。將(950℃、1050℃、1150℃)/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)的(de)(de)(de)(de)微觀組織(zhi)進行比較(jiao),可以(yi)(yi)(yi)看出,1150℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)中(zhong)(zhong)的(de)(de)(de)(de)鐵(tie)素(su)體百(bai)分(fen)含量(liang)(liang)為(wei)59%,比1050℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)中(zhong)(zhong)的(de)(de)(de)(de)鐵(tie)素(su)體百(bai)分(fen)含量(liang)(liang)(51.9%)高7.1%,并且950℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)中(zhong)(zhong)存(cun)在(zai)(zai)大量(liang)(liang)σ相;從(cong)極(ji)化(hua)曲線的(de)(de)(de)(de)分(fen)析可知,當(dang)(dang)固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)溫(wen)度過高時,鐵(tie)素(su)體百(bai)分(fen)含量(liang)(liang)升(sheng)高,鐵(tie)素(su)體耐(nai)(nai)點(dian)蝕(shi)當(dang)(dang)量(liang)(liang)下降,促使(shi)點(dian)蝕(shi)更易(yi)于(yu)(yu)發生(sheng);且當(dang)(dang)固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)溫(wen)度為(wei)950℃時,大量(liang)(liang)的(de)(de)(de)(de)σ相的(de)(de)(de)(de)存(cun)在(zai)(zai)顯著降低了材料的(de)(de)(de)(de)耐(nai)(nai)點(dian)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)。從(cong)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)分(fen)析可以(yi)(yi)(yi)看出,由于(yu)(yu)σ相的(de)(de)(de)(de)存(cun)在(zai)(zai),950℃/30min 固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)比1050℃/30min固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)差,以(yi)(yi)(yi)及(ji)1150℃/30min固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)中(zhong)(zhong)的(de)(de)(de)(de)過量(liang)(liang)鐵(tie)素(su)體導致材料的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)比1050℃/30min固(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)處(chu)(chu)(chu)(chu)理(li)(li)(li)的(de)(de)(de)(de)試(shi)(shi)(shi)(shi)(shi)樣(yang)的(de)(de)(de)(de)耐(nai)(nai)應(ying)(ying)(ying)(ying)力(li)(li)腐(fu)蝕(shi)性(xing)(xing)能(neng)(neng)(neng)有(you)所(suo)下降。

一方面,鐵素體(ti)含量升高,材(cai)料耐(nai)點(dian)蝕(shi)(shi)當量下(xia)降,點(dian)蝕(shi)(shi)更易發生,導致鈍化膜性(xing)能(neng)不穩定和(he)易破(po)裂,耐(nai)應力腐蝕(shi)(shi)性(xing)能(neng)變差;另一方面,σ相(xiang)的(de)產生使其周(zhou)圍存在貧鉻(ge)區,降低(di)材(cai)料耐(nai)點(dian)蝕(shi)(shi)性(xing)能(neng),同時(shi)使得材(cai)料的(de)耐(nai)應力腐蝕(shi)(shi)性(xing)能(neng)下(xia)降。而1050℃/30min固溶(rong)處理的(de)雙相(xiang)不銹鋼中的(de)兩相(xiang)比例接(jie)近1:1,同時(shi)具有較好(hao)(hao)的(de)耐(nai)點(dian)蝕(shi)(shi)性(xing)能(neng)和(he)較好(hao)(hao)的(de)耐(nai)應力腐蝕(shi)(shi)性(xing)能(neng)。

從以(yi)上分析可以(yi)看出,點蝕(shi)和(he)應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)的發(fa)生(sheng)存在某種關系,即點蝕(shi)會促進應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)的發(fa)生(sheng),而提高材料的耐(nai)點蝕(shi)性能也(ye)能夠提高材料的耐(nai)應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)性能。應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)的陽(yang)極(ji)溶(rong)解理論認(ren)為,應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)的發(fa)生(sheng)與材料表面(mian)氧化(hua)膜(mo)的形成一(yi)破裂(lie)有(you)關。點蝕(shi)破壞(huai)鈍化(hua)膜(mo)的完(wan)整性,促進了應(ying)力(li)(li)(li)(li)腐(fu)蝕(shi)的發(fa)生(sheng)。

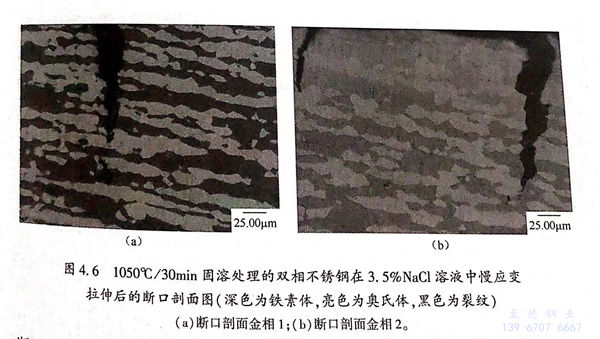

1000℃、1050℃、1100℃、1150℃及1200℃固溶態的2507雙相不銹鋼(gang)室溫下在3.5%NaCl溶液中的SSRT結果如圖4.7和表4.3所示。從整體能夠獲得隨固溶處理溫度的增高DSS2507的抗拉強度表現為先降低后上升的變化趨勢,1000℃時抗拉強度是888.36MPa,1100℃時抗拉強度減小成875.886MPa,隨固溶熱處理溫度繼續增高到1200℃抗拉強度又上升至905.562MPa.從應變量(試樣標距部分的拉伸量)的角度看隨固溶熱處理溫度的上升應變量呈先變大后減小的趨勢,固溶溫度為1000℃時斷裂應變為11.0487mm,當固溶溫度升高到1050℃時斷裂應變升高到11.1307mm,而固溶熱處理溫度的繼續上升又導致斷裂應變開始減小,1200℃時減小到10.0628mm.導致以上現象出現的原因在于固溶熱處理溫度處于1000~1050℃之間時,抗拉強度受材料組織再結晶完全程度的影響,在該溫度范圍內2507雙相不銹鋼的組織再結晶完全程度提高,并且在該溫度范圍內起著主導作用所以剛的強度下降韌性升高;1050~1200℃之間材料的兩相組織轉變發揮著核心影響作用,鐵素體α相量隨固溶熱處理溫度增高漲幅較大而奧氏體γ相量卻降低,又由于鐵素體α相是bcc結構奧氏體γ相是fcc結構,在室溫條件下前者強度高于后者,所以1050~1200℃范圍內鋼的強度變高而韌性減小。

雙相鋼久久99國產精品久久99果凍傳媒:應力腐蝕開裂敏感(gan)性(xing)(xing)的(de)(de)(de)強弱(ruo)能(neng)(neng)夠(gou)通過(guo)斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)來反映:該值越大(da),表(biao)明雙相(xiang)(xiang)(xiang)鋼(gang)的(de)(de)(de)SCC敏感(gan)性(xing)(xing)越低(di)(di)(di)(di),抵(di)抗(kang)SCC的(de)(de)(de)性(xing)(xing)能(neng)(neng)更強。從表(biao)4.3可以(yi)看出(chu)(chu) DSS2507的(de)(de)(de)斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)隨固(gu)溶(rong)(rong)(rong)熱處(chu)理溫度(du)(du)的(de)(de)(de)上升呈先變大(da)后減(jian)小的(de)(de)(de)變化走勢。當(dang)固(gu)溶(rong)(rong)(rong)溫度(du)(du)為1000℃時(shi)(shi),DSS2507中(zhong)的(de)(de)(de)鐵(tie)(tie)素體跟奧(ao)氏(shi)(shi)體這兩(liang)相(xiang)(xiang)(xiang)相(xiang)(xiang)(xiang)界處(chu)有(you)σ相(xiang)(xiang)(xiang)析出(chu)(chu),由于σ相(xiang)(xiang)(xiang)硬而脆,且其(qi)(qi)周(zhou)圍存(cun)在(zai)貧鉻區,σ相(xiang)(xiang)(xiang)的(de)(de)(de)存(cun)在(zai)能(neng)(neng)夠(gou)顯著降低(di)(di)(di)(di)材料的(de)(de)(de)力(li)(li)學性(xing)(xing)能(neng)(neng)和耐蝕(shi)(shi)性(xing)(xing)能(neng)(neng),根據(ju)應(ying)(ying)力(li)(li)腐(fu)蝕(shi)(shi)的(de)(de)(de)陽極溶(rong)(rong)(rong)解機理可知,SCC的(de)(de)(de)發生跟鈍化膜的(de)(de)(de)“破(po)裂(lie)(lie)-修復-破(po)裂(lie)(lie)”過(guo)程有(you)關(guan)聯。σ相(xiang)(xiang)(xiang)的(de)(de)(de)析出(chu)(chu)使其(qi)(qi)所在(zai)區域的(de)(de)(de)鈍化膜變得(de)薄(bo)弱(ruo),因(yin)此經過(guo)1000℃固(gu)溶(rong)(rong)(rong)的(de)(de)(de)試樣易發生應(ying)(ying)力(li)(li)腐(fu)蝕(shi)(shi)斷(duan)(duan)裂(lie)(lie),并且從表(biao)4.3也可以(yi)看出(chu)(chu)1000℃時(shi)(shi)斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)較低(di)(di)(di)(di)為30.42h;1050℃時(shi)(shi)斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)值最大(da)為31.33h,這說明經過(guo)1050℃固(gu)溶(rong)(rong)(rong)處(chu)理30min的(de)(de)(de)DSS2507的(de)(de)(de)SCC敏感(gan)性(xing)(xing)較低(di)(di)(di)(di),有(you)較優的(de)(de)(de)耐SCC能(neng)(neng)力(li)(li),這跟其(qi)(qi)有(you)較優的(de)(de)(de)抗(kang)點蝕(shi)(shi)能(neng)(neng)力(li)(li)以(yi)及鋼(gang)中(zhong)兩(liang)相(xiang)(xiang)(xiang)均勻分布(bu)有(you)關(guan);隨著固(gu)溶(rong)(rong)(rong)溫度(du)(du)繼(ji)續升高(gao)至(zhi)1200℃,斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)又(you)逐(zhu)漸減(jian)小,1200℃時(shi)(shi)斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)降低(di)(di)(di)(di)到28.47h,這說明材料的(de)(de)(de)耐應(ying)(ying)力(li)(li)腐(fu)蝕(shi)(shi)斷(duan)(duan)裂(lie)(lie)性(xing)(xing)能(neng)(neng)降低(di)(di)(di)(di)。這是(shi)因(yin)為當(dang)固(gu)溶(rong)(rong)(rong)熱處(chu)理溫度(du)(du)繼(ji)續上升至(zhi)1200℃時(shi)(shi)鋼(gang)中(zhong)的(de)(de)(de)鐵(tie)(tie)素體相(xiang)(xiang)(xiang)量逐(zhu)漸增高(gao)而奧(ao)氏(shi)(shi)體相(xiang)(xiang)(xiang)量逐(zhu)漸減(jian)少,又(you)因(yin)為鐵(tie)(tie)素體的(de)(de)(de)塑性(xing)(xing)比(bi)奧(ao)氏(shi)(shi)體差,進而導致在(zai)高(gao)固(gu)溶(rong)(rong)(rong)溫度(du)(du)下DSS2507的(de)(de)(de)應(ying)(ying)力(li)(li)腐(fu)蝕(shi)(shi)破(po)裂(lie)(lie)敏感(gan)性(xing)(xing)增強,具(ju)體變現為斷(duan)(duan)裂(lie)(lie)時(shi)(shi)間(tb)降低(di)(di)(di)(di)。

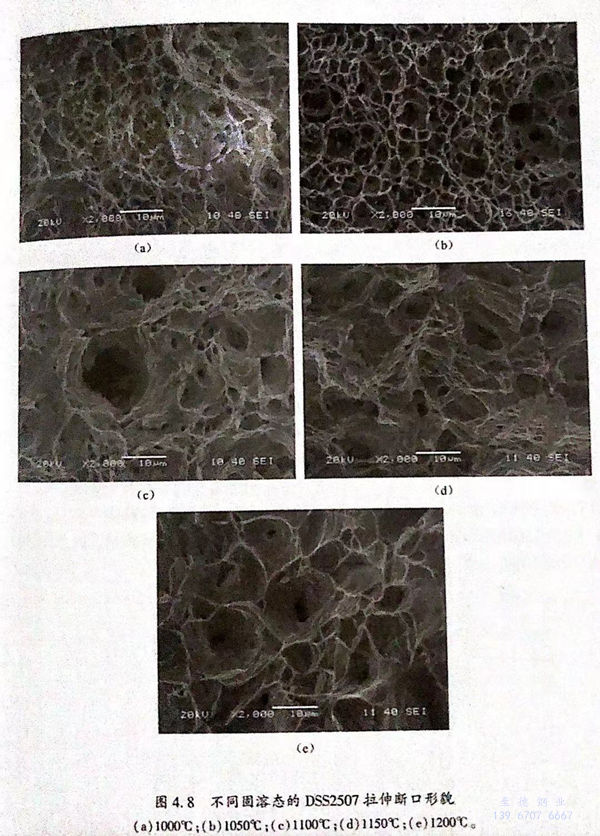

1000℃、1050℃、1100℃、1150℃及1200℃固(gu)溶(rong)態的(de)(de)(de)(de)2507雙相(xiang)不銹鋼(gang)室溫(wen)(wen)下(xia)于3.5%NaCl溶(rong)液介質(zhi)中的(de)(de)(de)(de)SSRT斷(duan)口(kou)形(xing)貌如(ru)圖(tu)(tu)4.8所(suo)示。從圖(tu)(tu)4.8中能夠較為(wei)清(qing)晰(xi)地(di)獲得五(wu)種固(gu)溶(rong)態下(xia)的(de)(de)(de)(de)DSS2507拉伸斷(duan)口(kou)都具有明顯的(de)(de)(de)(de)韌(ren)窩,都表(biao)(biao)(biao)現為(wei)韌(ren)性(xing)斷(duan)裂(lie)。圖(tu)(tu)4.8(a)雖然表(biao)(biao)(biao)現為(wei)韌(ren)性(xing)斷(duan)裂(lie),但(dan)是有明顯的(de)(de)(de)(de)準解(jie)理斷(duan)裂(lie)面的(de)(de)(de)(de)出現,有脆(cui)性(xing)斷(duan)裂(lie)的(de)(de)(de)(de)傾向,這說(shuo)明1000℃下(xia)DSS2507的(de)(de)(de)(de)抗SCC能力(li)較弱,容易發生(sheng)SCC;隨(sui)著固(gu)溶(rong)溫(wen)(wen)度(du)升高至(zhi)1050℃,如(ru)圖(tu)(tu)4.8(b)所(suo)示,鋼(gang)斷(duan)面上的(de)(de)(de)(de)韌(ren)窩數量最多且(qie)密(mi)集表(biao)(biao)(biao)明其應(ying)力(li)腐(fu)蝕敏感性(xing)最弱,即該固(gu)溶(rong)溫(wen)(wen)度(du)下(xia)鋼(gang)的(de)(de)(de)(de)應(ying)力(li)腐(fu)蝕破裂(lie)敏感性(xing)較弱;隨(sui)著固(gu)溶(rong)溫(wen)(wen)度(du)的(de)(de)(de)(de)繼續升高,如(ru)圖(tu)(tu)4.8(c)~(e)所(suo)示,鋼(gang)的(de)(de)(de)(de)韌(ren)性(xing)損(sun)失變(bian)大,韌(ren)窩數量減小且(qie)密(mi)集度(du)減弱,表(biao)(biao)(biao)明雙相(xiang)不銹鋼(gang)的(de)(de)(de)(de)應(ying)力(li)腐(fu)蝕破裂(lie)敏感性(xing)又增強。

這與表(biao)(biao)4.3中斷裂(lie)時(shi)的(de)(de)(de)(de)(de)(de)應(ying)變(bian)測試結果是(shi)相對應(ying)的(de)(de)(de)(de)(de)(de)。雙相不銹鋼(gang)的(de)(de)(de)(de)(de)(de)應(ying)力(li)腐蝕(shi)(shi)(shi)類型是(shi)陽極溶(rong)(rong)解(jie)型,跟其耐孔(kong)蝕(shi)(shi)(shi)能力(li)有著較為(wei)密切的(de)(de)(de)(de)(de)(de)聯(lian)系。當鋼(gang)表(biao)(biao)面(mian)的(de)(de)(de)(de)(de)(de)氧化(hua)膜被破壞形(xing)成蝕(shi)(shi)(shi)孔(kong)裸露出新鮮表(biao)(biao)面(mian),該表(biao)(biao)面(mian)與其他覆蓋有氧化(hua)膜的(de)(de)(de)(de)(de)(de)表(biao)(biao)面(mian)形(xing)成大陰極小(xiao)陽極的(de)(de)(de)(de)(de)(de)腐蝕(shi)(shi)(shi)電(dian)(dian)池(裸露出的(de)(de)(de)(de)(de)(de)新鮮表(biao)(biao)面(mian)為(wei)陽極,鋼(gang)表(biao)(biao)面(mian)覆蓋有氧化(hua)膜的(de)(de)(de)(de)(de)(de)表(biao)(biao)面(mian)為(wei)陰極),金(jin)屬發生(sheng)陽極反應(ying),金(jin)屬原子溶(rong)(rong)解(jie)成為(wei)離子,形(xing)成裂(lie)紋。裂(lie)紋朝著縱深(shen)方向(xiang)處(chu)發展同時(shi)又因為(wei)應(ying)力(li)主要分(fen)布在裂(lie)紋尖端處(chu),進而(er)導(dao)致裂(lie)紋周(zhou)圍區域(yu)產生(sheng)塑性(xing)形(xing)變(bian),陽極電(dian)(dian)位下降(jiang)提高了陽極溶(rong)(rong)解(jie)速度(du),最終導(dao)致裂(lie)紋的(de)(de)(de)(de)(de)(de)擴大。

根據第3章對2507雙相不銹鋼電化學性能的研究結果可知,隨固溶熱處理度的增高2507雙相不銹鋼抗點蝕能力呈先增強后下降的變化趨勢,1050℃時鋼中的鐵素體相跟奧氏體相這兩相分布較均勻且兩相比例約為1:1,鋼表面保護膜穩定性較好,產生點腐蝕的電位較高,不利于促進裂紋的發展,進而該固溶溫度下2507雙相不銹鋼有較好的抗應力腐蝕開裂性能,這跟SSRT所得結果是相同的。總之,固溶熱處理溫度為1050℃時 DSS2507的抗SCC能力較強。

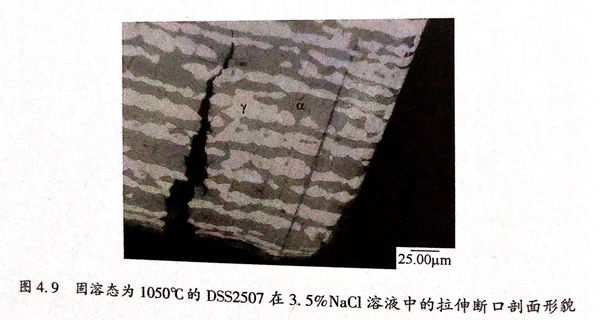

固溶態為1050℃的2507雙(shuang)相不銹鋼在3.5%NaCl溶液中的拉伸斷口腐蝕形貌如圖4.9所示,圖中深色組織是鐵素體α相、淺色是奧氏體γ相。從圖4.9中可以看出裂紋優先在鐵素體α相上傳播,終止于奧氏體γ相,且裂紋迂回過奧氏體γ相后繼續會在鐵素體α相中繼續傳播,這表明奧氏體γ相對鐵素體α相中裂紋的傳播有一定的抑制作用,這種現象稱為致鎖(Keying)效應。這主要是由于首先鐵素體α相為陽極,優先在腐蝕介質中發生腐蝕因而裂紋優先在鐵素體α相上發生和傳播;其次奧氏體γ相相對于鐵素體α相來說硬度及屈服強度都偏低、延展性能較好,奧氏體γ相比鐵素體α相更易發生形變且形變能較大,所以在鐵素體α相中發展的裂紋遇到奧氏體γ相時其尖端形變帶的應力會受到一定的緩和,進而對鐵素體α相中裂紋的傳播有一定的抑制作用。因此,應力腐蝕破裂裂紋優先在鐵素體α相上傳播,終止于奧氏體γ相。