奧氏體不銹鋼采用手工鎢極氬弧焊可以進行各種位置的操作,其中包括水平固定管(全位置)的對接焊,但主適用于薄壁件和打底層的焊接。

根據接頭的形式(shi),平(ping)(ping)焊(han)位置包括對接平(ping)(ping)焊(han)和平(ping)(ping)角焊(han)兩種。

①. 對(dui)接平焊(han)

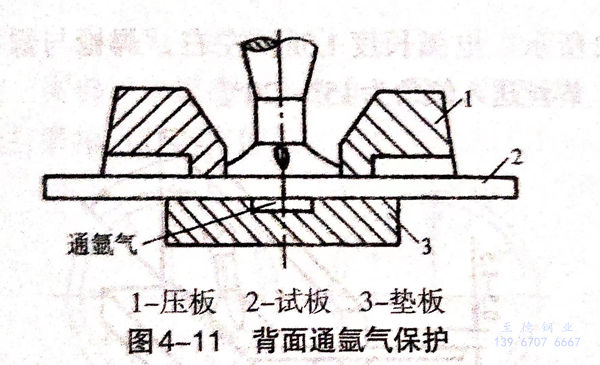

焊(han)件(jian)在裝(zhuang)配時,為了防(fang)止焊(han)接過程中(zhong)產生變形(xing),應放在夾具中(zhong)緊固(gu),并(bing)在焊(han)件(jian)坡口(kou)背面安(an)放墊板(ban)(ban),墊板(ban)(ban)上應開設凹槽,內通氬氣,保護背面焊(han)縫,如(ru)圖(tu)4-11所示(shi)。

焊(han)(han)接時,首先在(zai)定位焊(han)(han)縫(feng)根部(bu)后10mm左右(you)處(chu)(chu)開始引燃(ran)電弧(hu),運弧(hu)至定位焊(han)(han)點(dian)根部(bu),此時焊(han)(han)槍畫一個半圓形(xing)的圈,在(zai)坡(po)口根部(bu)形(xing)成一個熔(rong)孔(kong),熔(rong)孔(kong)形(xing)成后向(xiang)右(you)側鈍邊處(chu)(chu)填加焊(han)(han)絲(si),然后得向(xiang)左側運弧(hu),向(xiang)左側鈍邊處(chu)(chu)填加焊(han)(han)絲(si),再向(xiang)右(you)運弧(hu),如(ru)此往(wang)復循環,逐漸形(xing)成熔(rong)透焊(han)(han)縫(feng)。

操作過程中要(yao)保持熔(rong)(rong)(rong)孔(kong)始終深入母(mu)材(cai)0.5~1.0mm,出現(xian)熔(rong)(rong)(rong)孔(kong)后應立即填充焊(han)(han)(han)(han)絲,這時形(xing)成(cheng)(cheng)的(de)焊(han)(han)(han)(han)縫(feng)(feng)才會(hui)均勻。如果(guo)填充焊(han)(han)(han)(han)絲過遲(chi),熔(rong)(rong)(rong)孔(kong)過大,反面焊(han)(han)(han)(han)縫(feng)(feng)就(jiu)過高(gao),甚至(zhi)產生焊(han)(han)(han)(han)瘤;填充焊(han)(han)(han)(han)絲過早,若還未形(xing)成(cheng)(cheng)熔(rong)(rong)(rong)孔(kong),就(jiu)會(hui)產生未焊(han)(han)(han)(han)透(tou)。焊(han)(han)(han)(han)接過程中在不影(ying)響視(shi)線的(de)情況(kuang)下盡量采用短弧,以增強氬氣的(de)保護效果(guo)和(he)提高(gao)電弧的(de)穿透(tou)能(neng)力。鎢極(ji)端部距(ju)熔(rong)(rong)(rong)池(chi)表面以2~3mm為(wei)宜,要(yao)注(zhu)意(yi)觀(guan)察熔(rong)(rong)(rong)池(chi)的(de)形(xing)狀,熔(rong)(rong)(rong)池(chi)應保持與(yu)焊(han)(han)(han)(han)縫(feng)(feng)軸線對稱,否(fou)則焊(han)(han)(han)(han)縫(feng)(feng)就(jiu)會(hui)偏斜(xie)。

熔(rong)(rong)透(tou)(tou)的(de)識(shi)別:焊(han)(han)接過程中(zhong)應(ying)通(tong)過仔細(xi)觀察(cha)熔(rong)(rong)池的(de)變(bian)化來判斷(duan)是否(fou)熔(rong)(rong)透(tou)(tou),以達到單面焊(han)(han)雙面成形的(de)目的(de)。當填充焊(han)(han)絲上一(yi)顆(ke)熔(rong)(rong)滴落入熔(rong)(rong)池時,熔(rong)(rong)池表(biao)面位(wei)置就會(hui)(hui)升高,隨著熱量向下傳輸,基本(ben)金屬熔(rong)(rong)化形成熔(rong)(rong)孔。由于(yu)重(zhong)(zhong)力使熔(rong)(rong)池下沉,于(yu)是熔(rong)(rong)池水(shui)平(ping)下降,熔(rong)(rong)池表(biao)面積擴張,這是焊(han)(han)透(tou)(tou)的(de)重(zhong)(zhong)要標志。如果沒有焊(han)(han)透(tou)(tou),熔(rong)(rong)池便不(bu)會(hui)(hui)下沉。

當運弧(hu)至終焊(han)端(duan)的定(ding)(ding)位(wei)(wei)焊(han)縫(feng)根部3~5mm時,焊(han)槍(qiang)畫(hua)圈,把(ba)定(ding)(ding)位(wei)(wei)焊(han)縫(feng)根部熔(rong)化,然后(hou)填充2~3滴熔(rong)滴,繼續(xu)向前施焊(han)10mm左(zuo)右(you),把(ba)定(ding)(ding)位(wei)(wei)焊(han)縫(feng)表面熔(rong)化,最后(hou)用電流(liu)衰減(jian)法(fa)收弧(hu)。收弧(hu)焊(han)縫(feng)應在定(ding)(ding)位(wei)(wei)焊(han)縫(feng)后(hou)方10mm左(zuo)右(you)處,以(yi)保證(zheng)接頭部位(wei)(wei)能焊(han)透。

②. 平(ping)角焊

操作時,焊槍、焊絲(si)和(he)焊件之間的(de)相對位(wei)置如(ru)圖4-12所示。電(dian)弧長(chang)度1.5mm左右,焊槍與焊件的(de)傾角為40°~50°,焊絲(si)送(song)入傾角為15°~20°。